/div>

Hand in hand

Hand in hand

From consulting to engineering to construction, our customers receive all services from a single source – us. An experienced, well-practised team of engineers, technicians, designers and fitters is happy to take on the challenge of working with you to build the ideal tank system for you on time. Our top priorities are guaranteeing the safety of people and the environment and satisfying our customers.

From consulting to engineering to construction, our customers receive all services from a single source – us. An experienced, well-practised team of engineers, technicians, designers and fitters is happy to take on the challenge of working with you to build the ideal tank system for you on time. Our top priorities are guaranteeing the safety of people and the environment and satisfying our customers.

In addition to focusing on the trouble-free completion of functioning tank systems, we are always looking for and developing optimised solutions. The results of this work include our own patents, such as the JPM SWING I floating roof seal, the SWING II floating roof seal and a rope guide for low-pressure gas storage tanks.

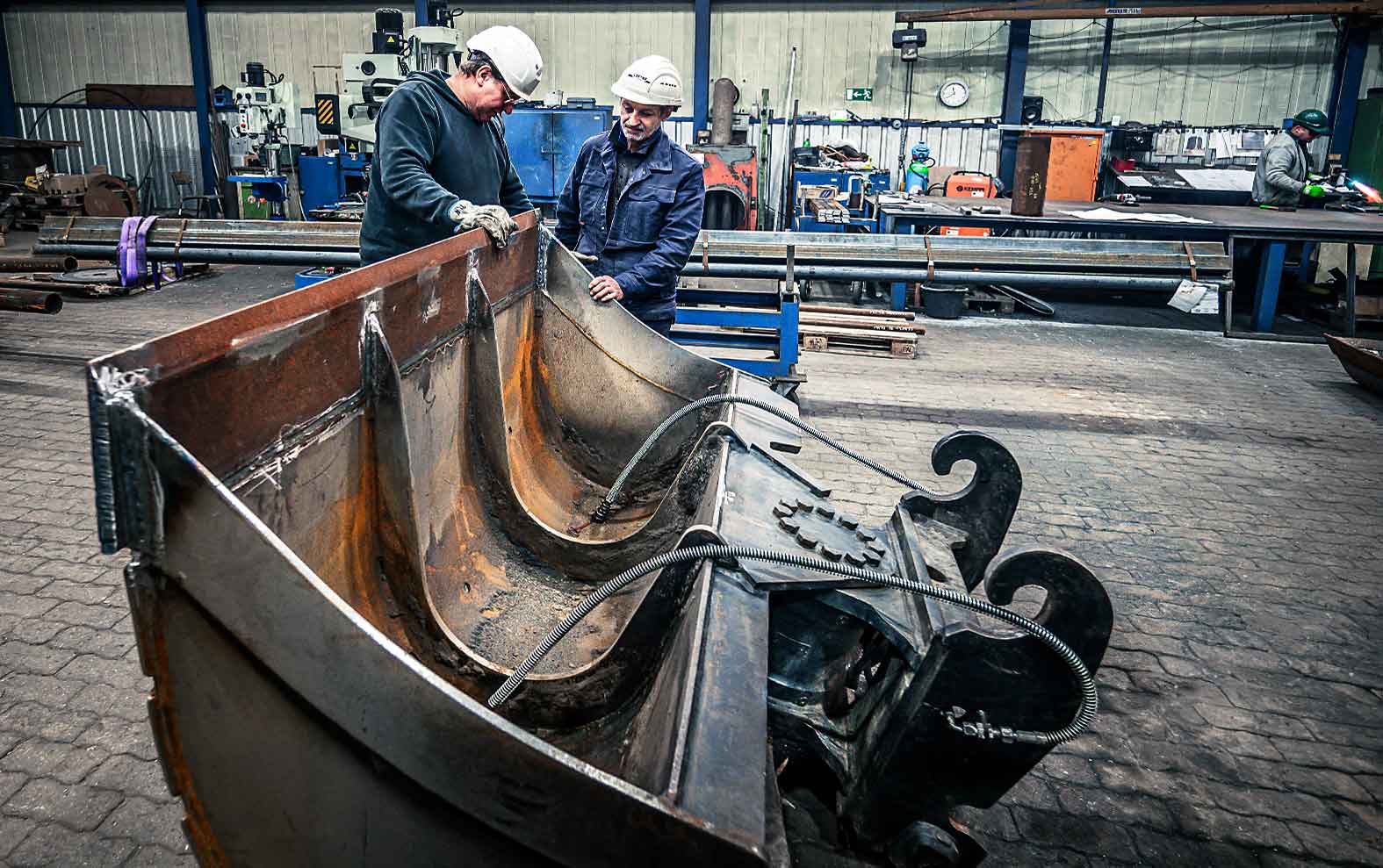

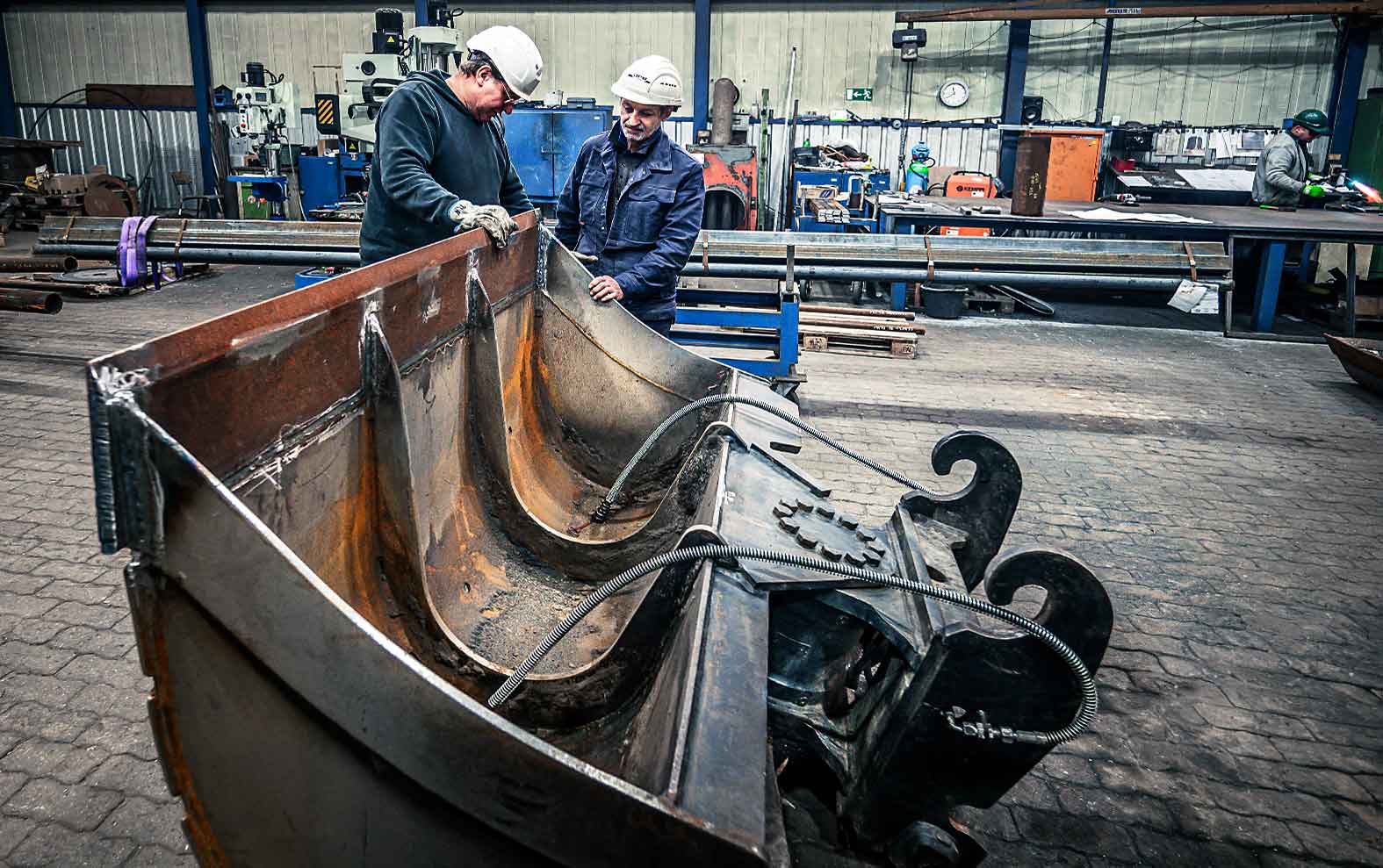

Not quite our core business, but also part of our range of services: repair of heavy equipment such as excavator buckets, push plates for bulldozers or mobile drilling on wheel loaders.

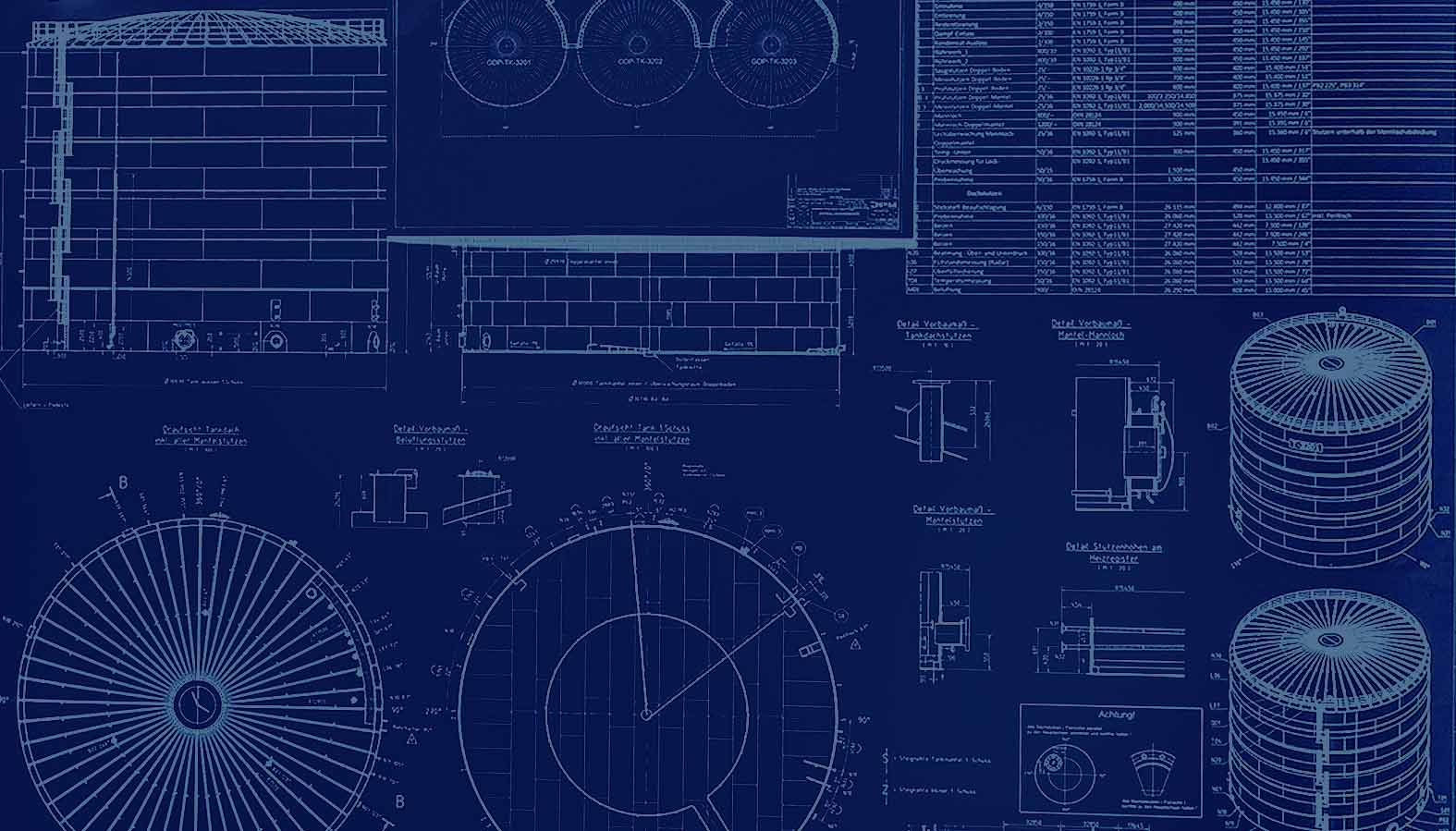

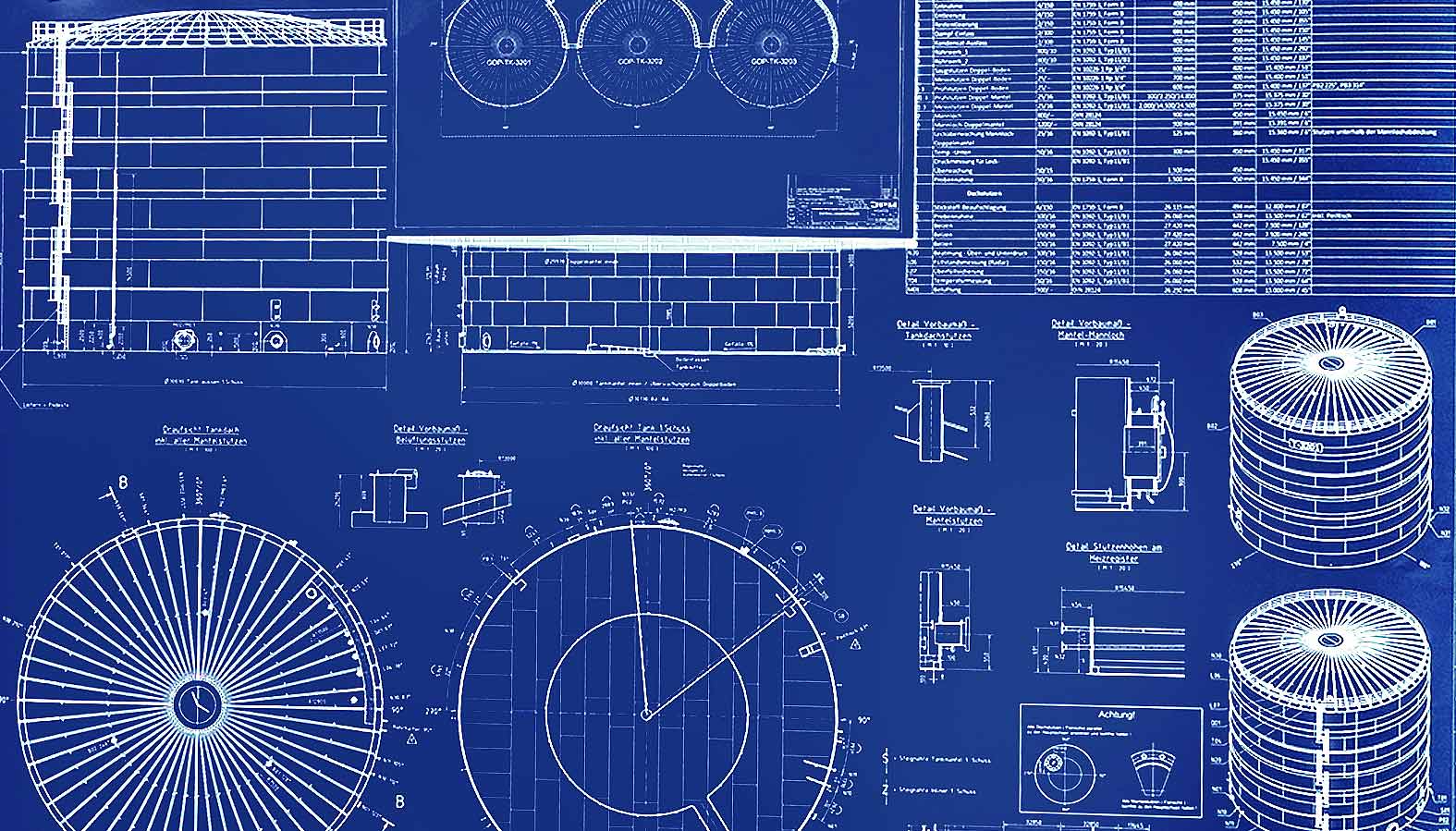

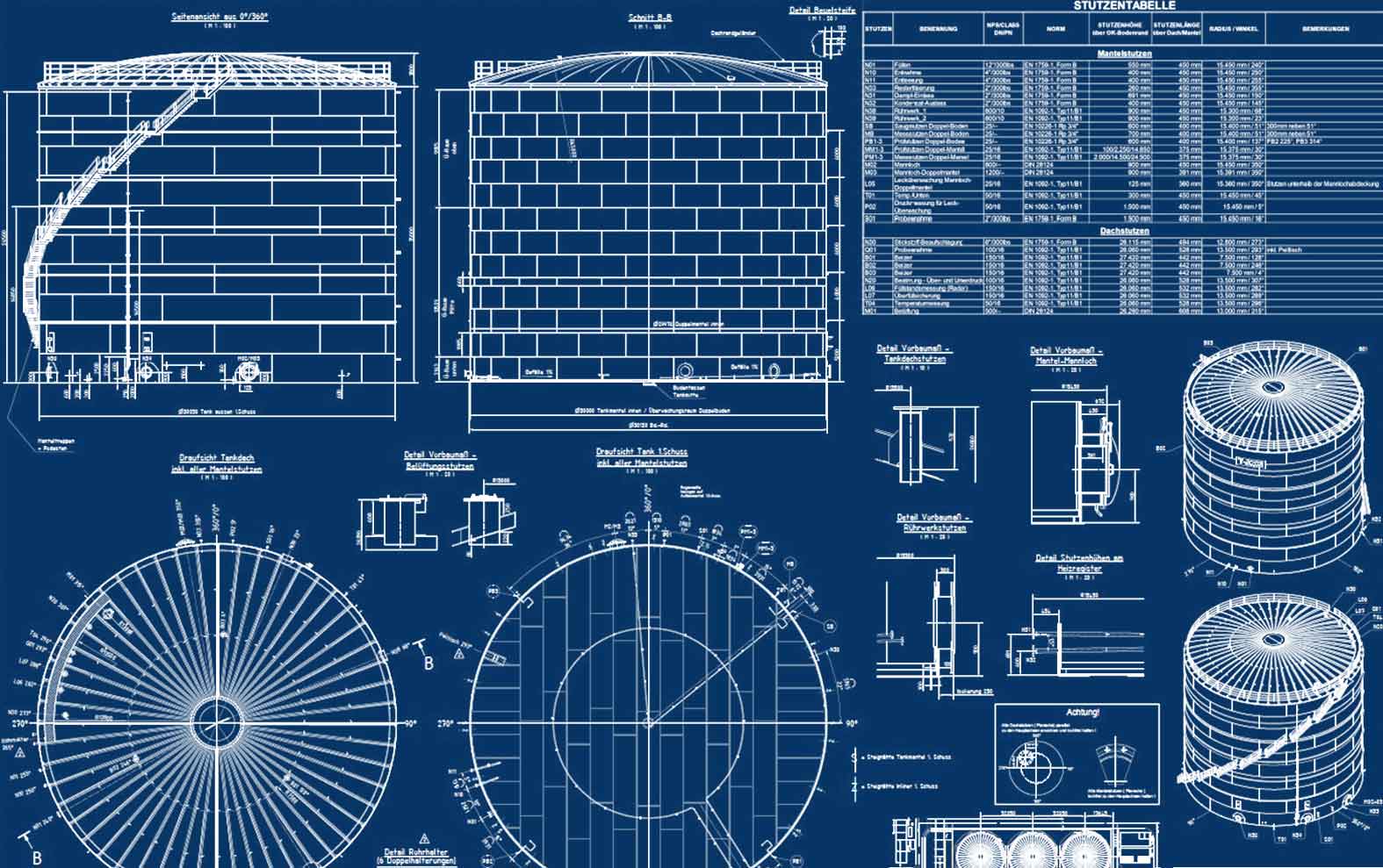

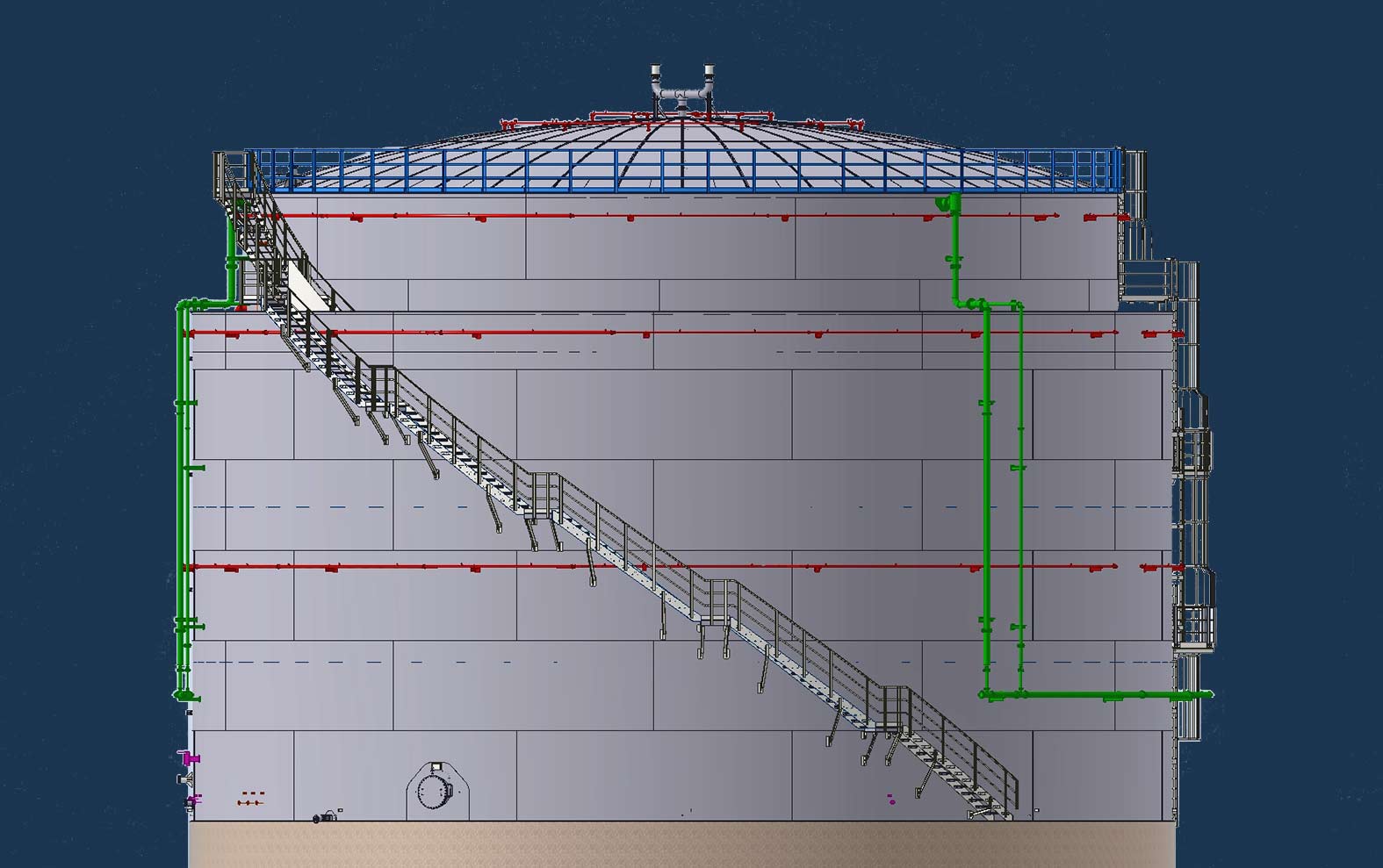

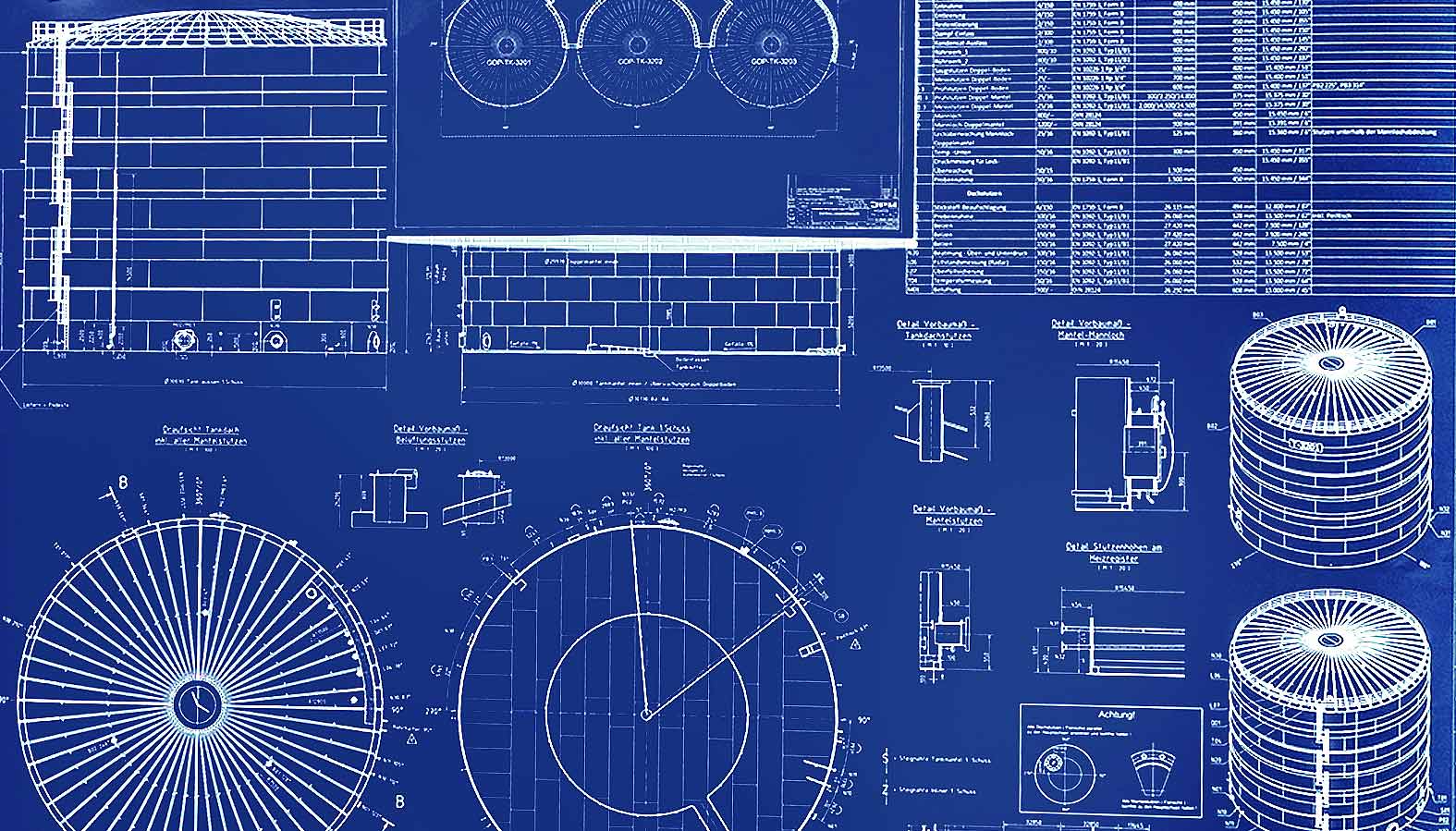

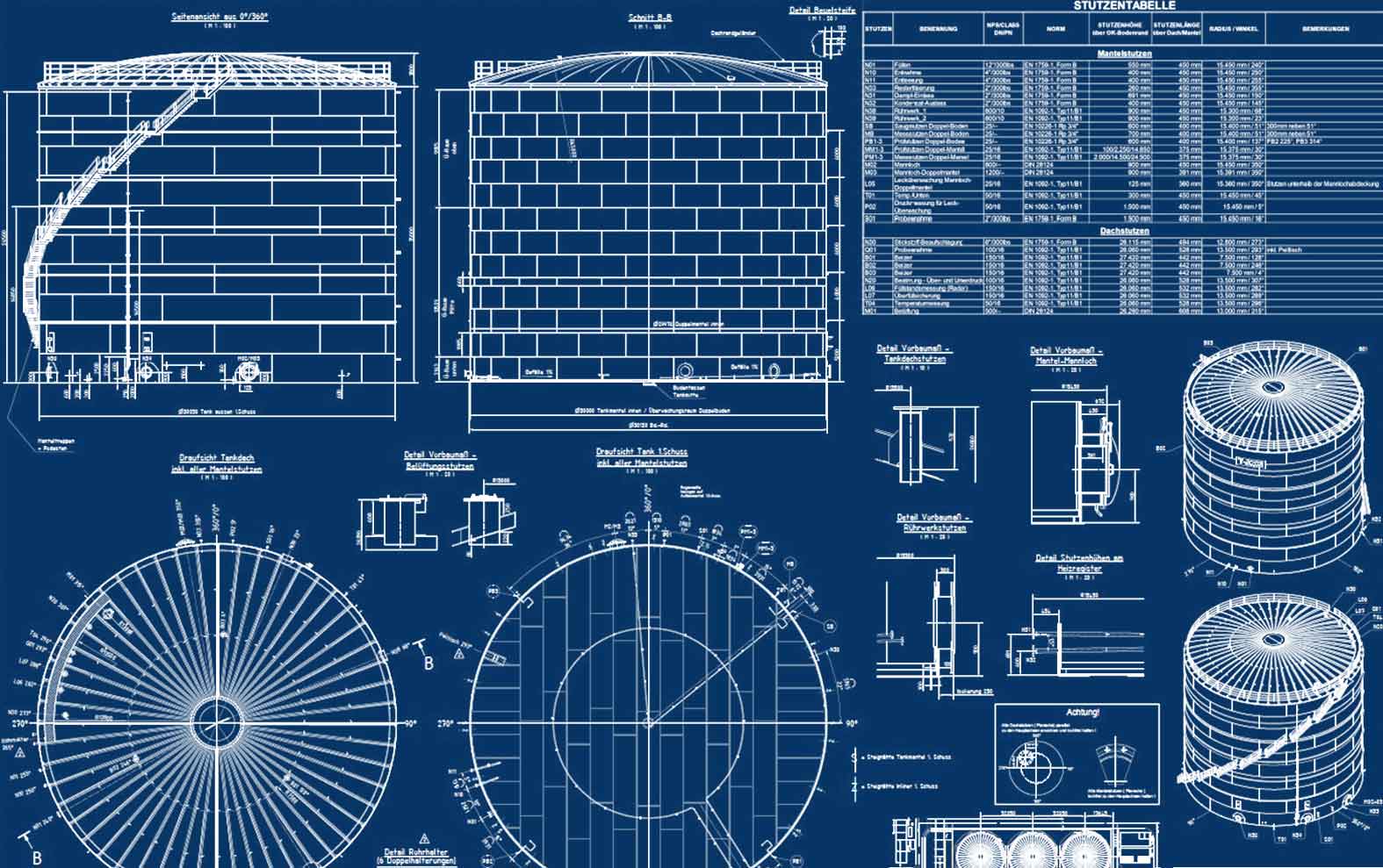

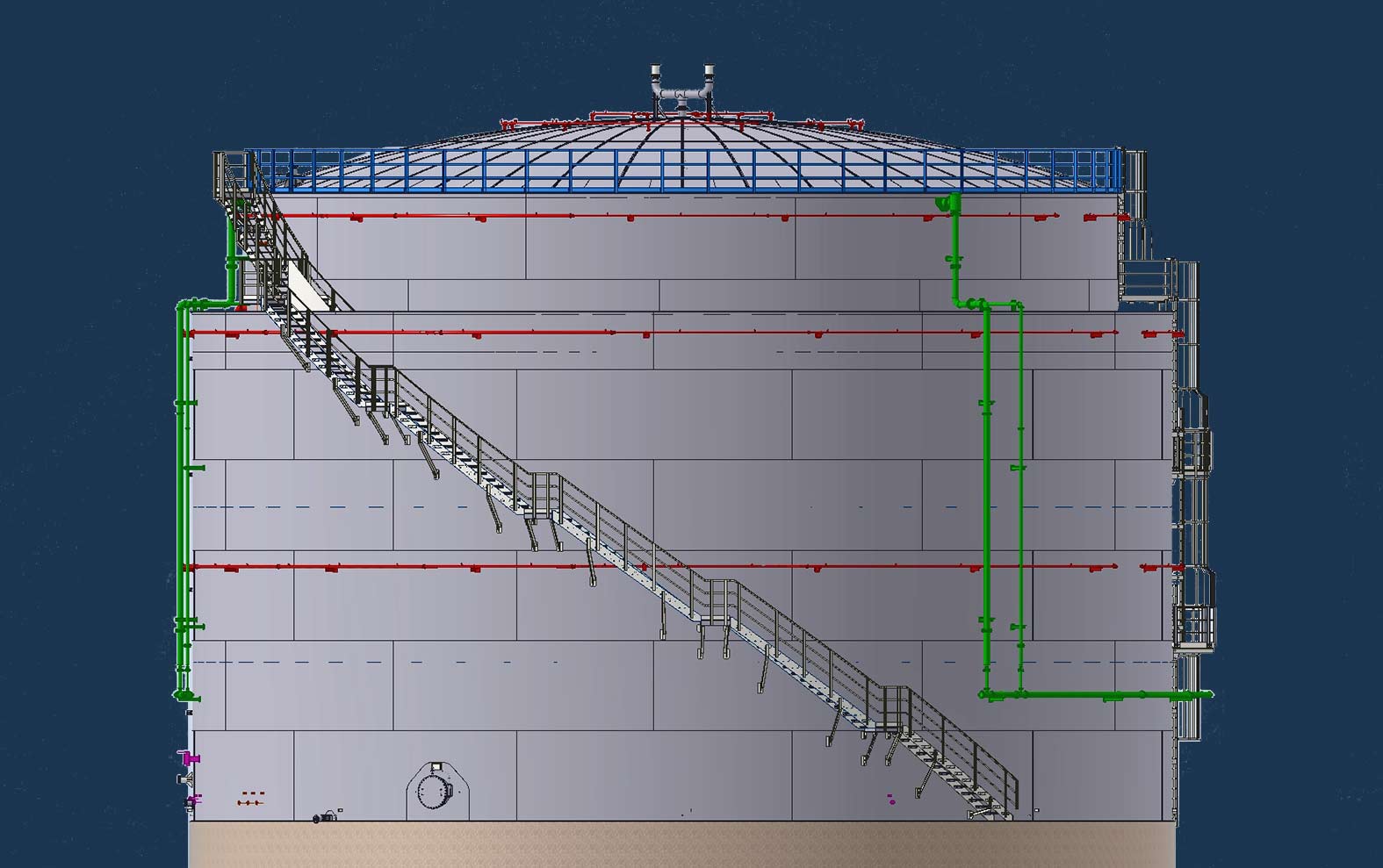

CAD overview drawing

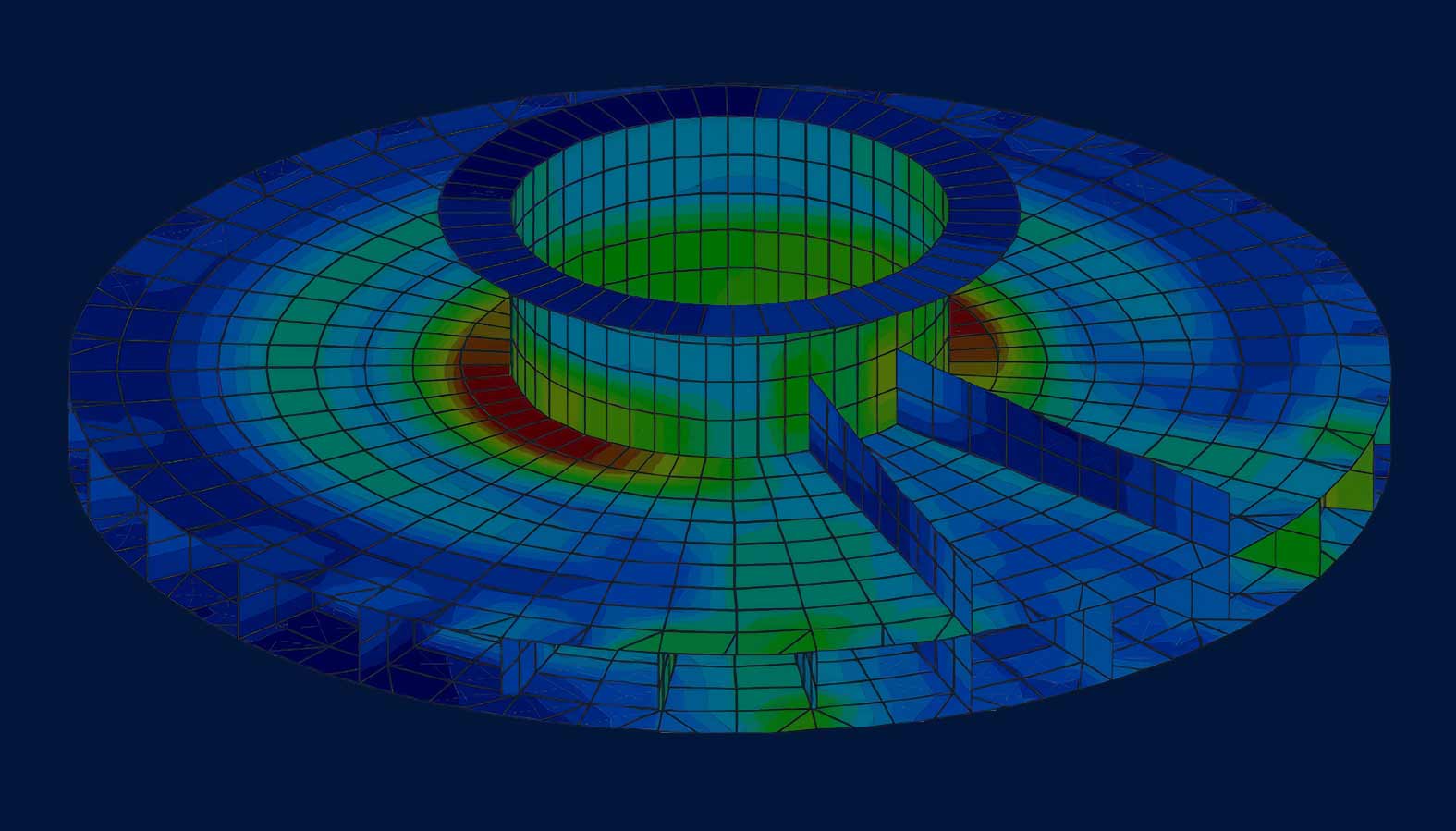

Creation of a 3D model

Bill of material

CAD drawing creation

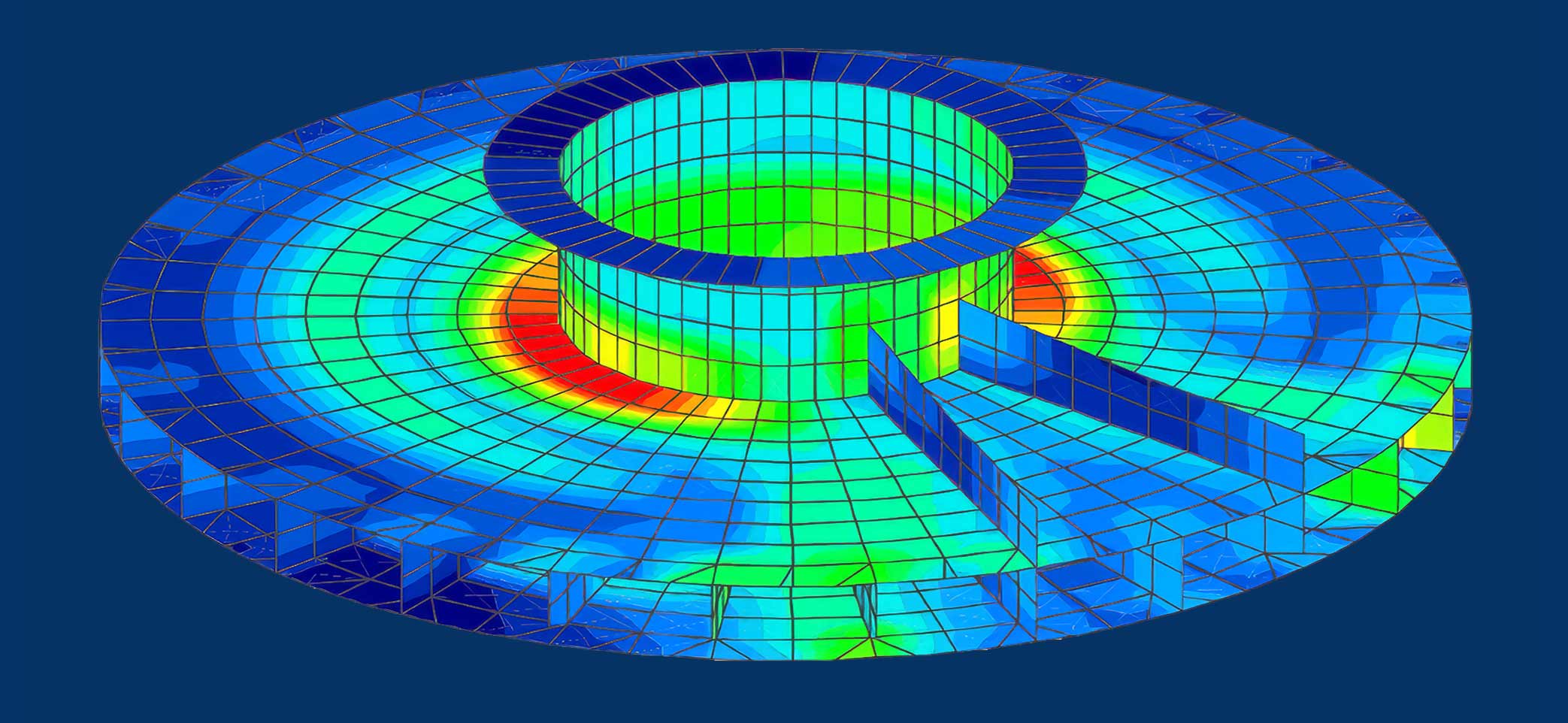

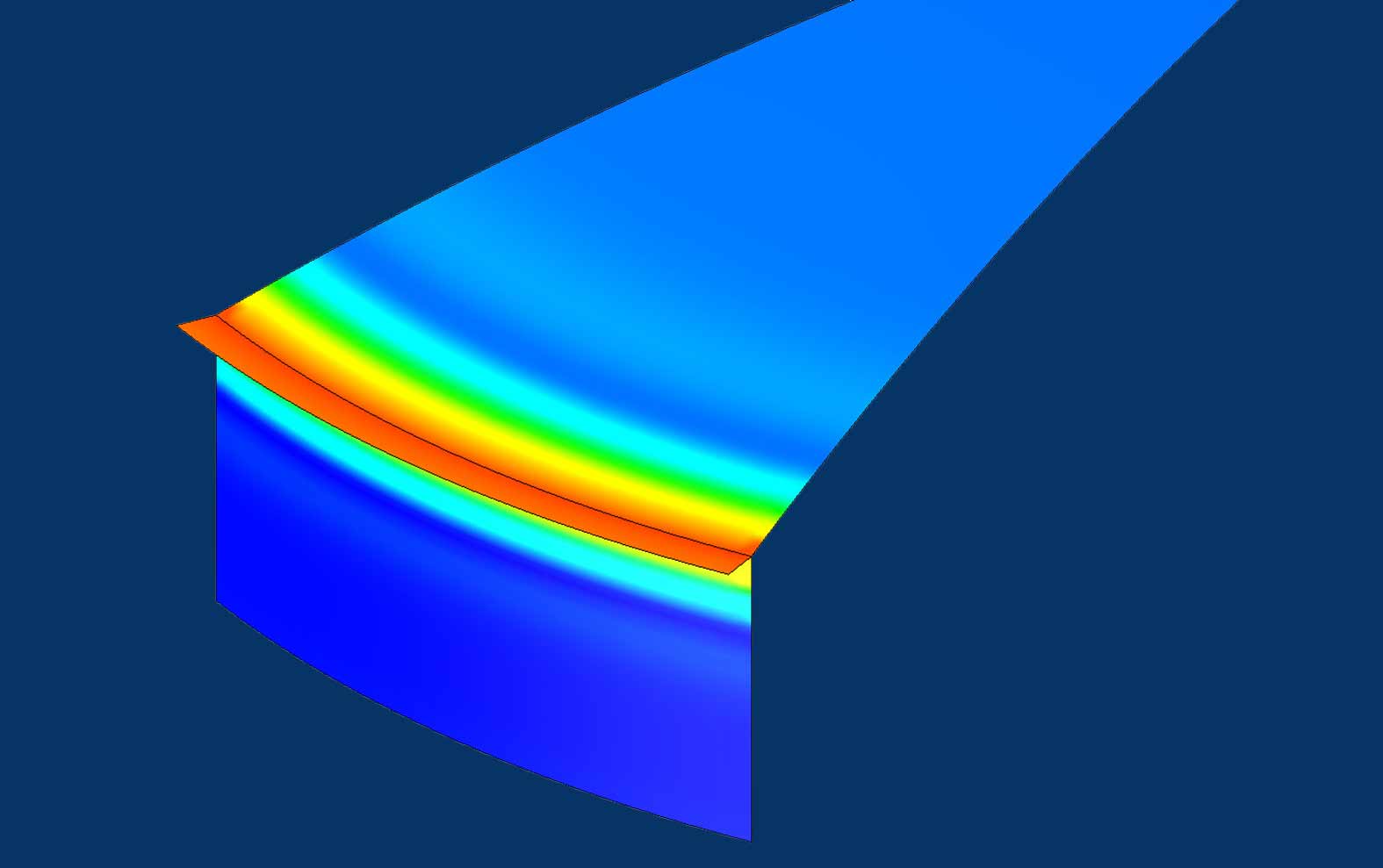

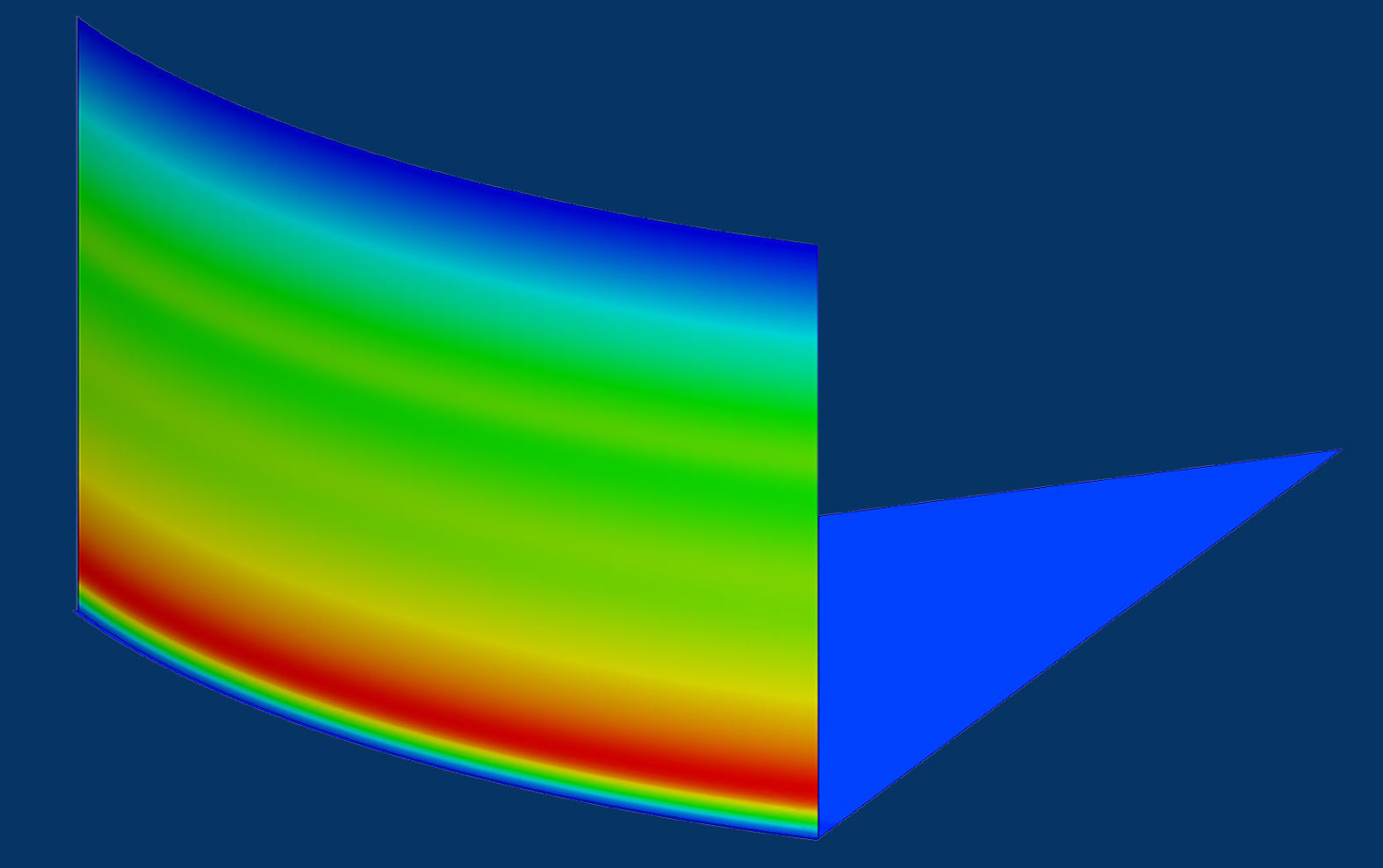

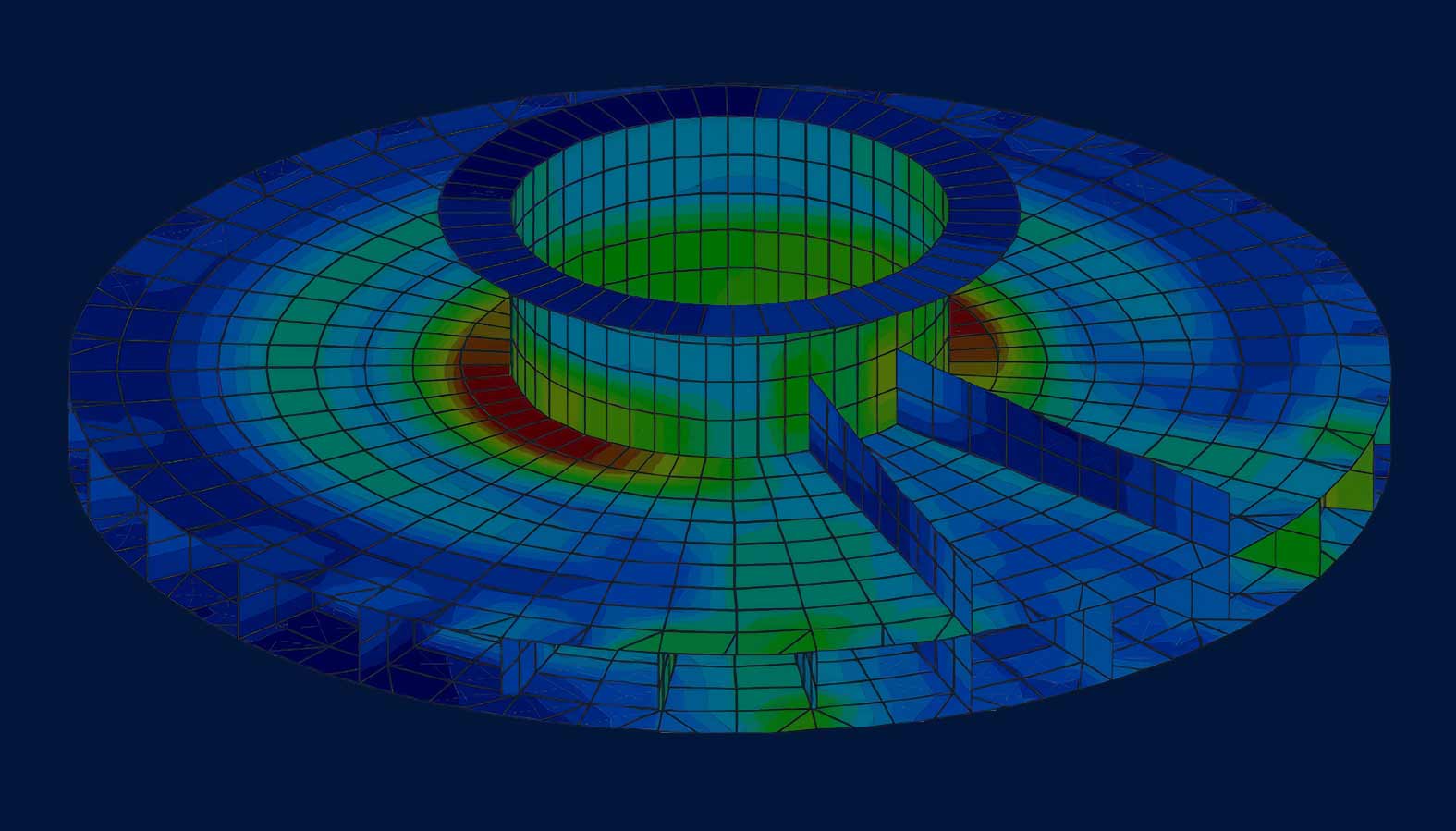

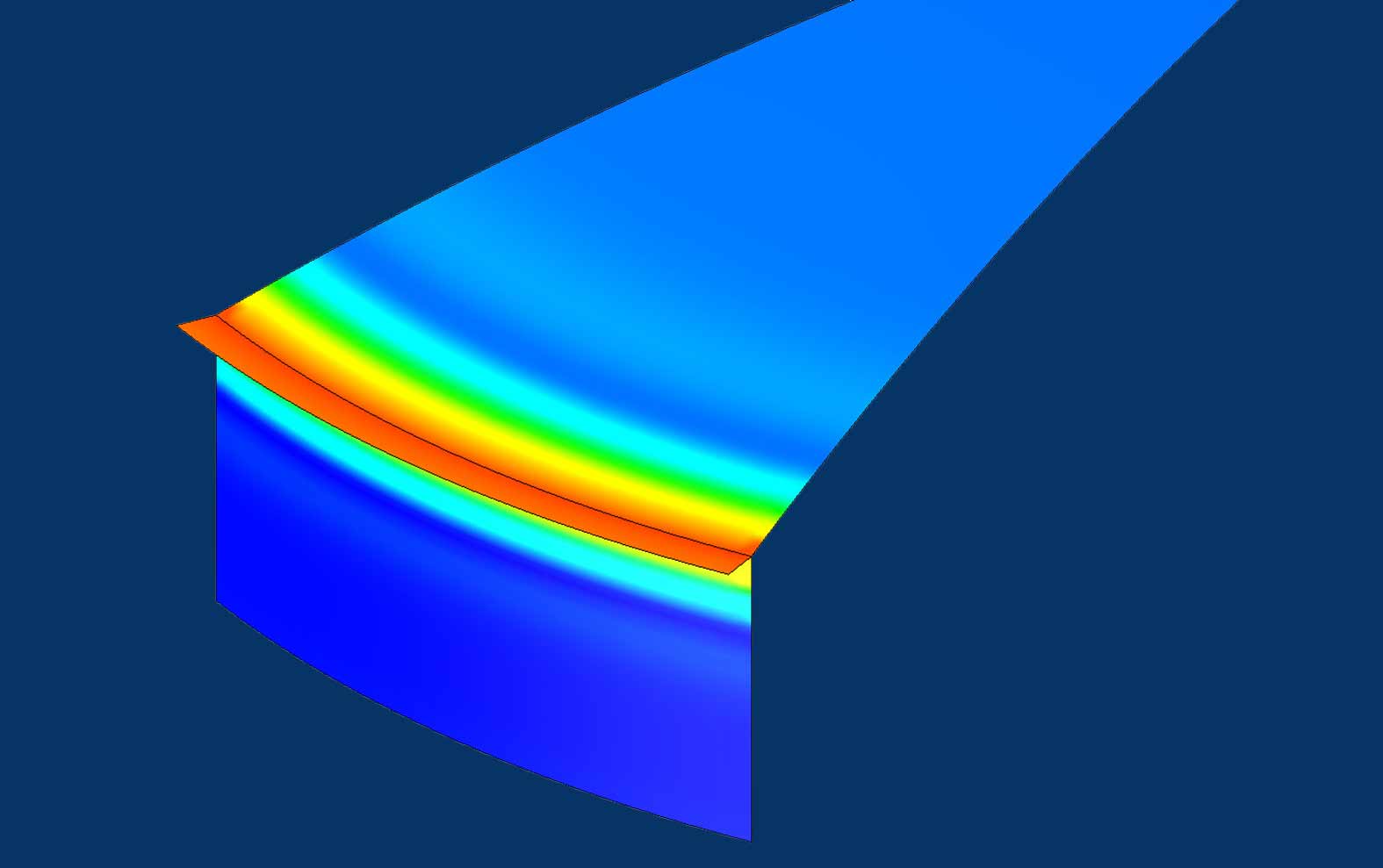

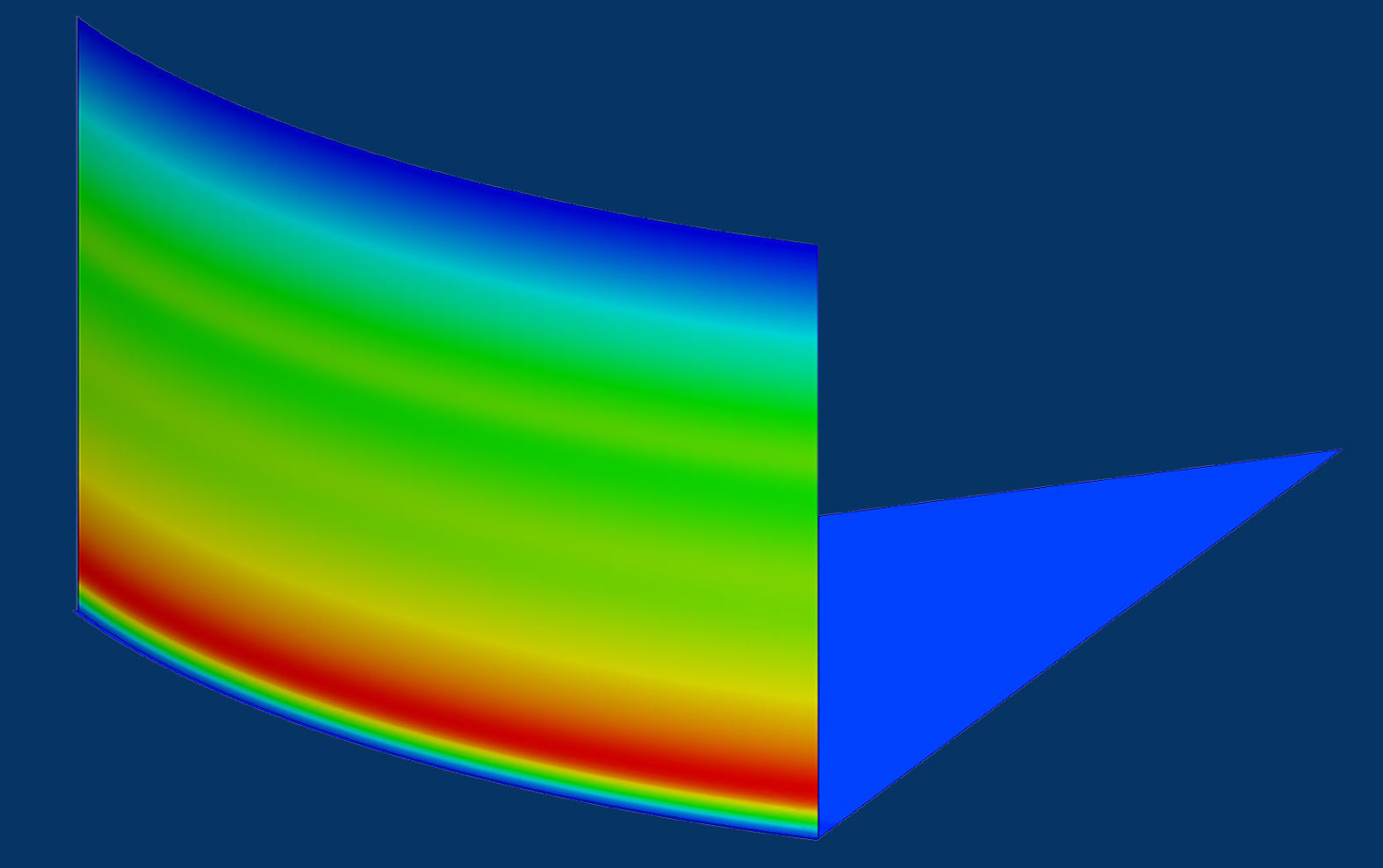

Fixed roof strength analysis

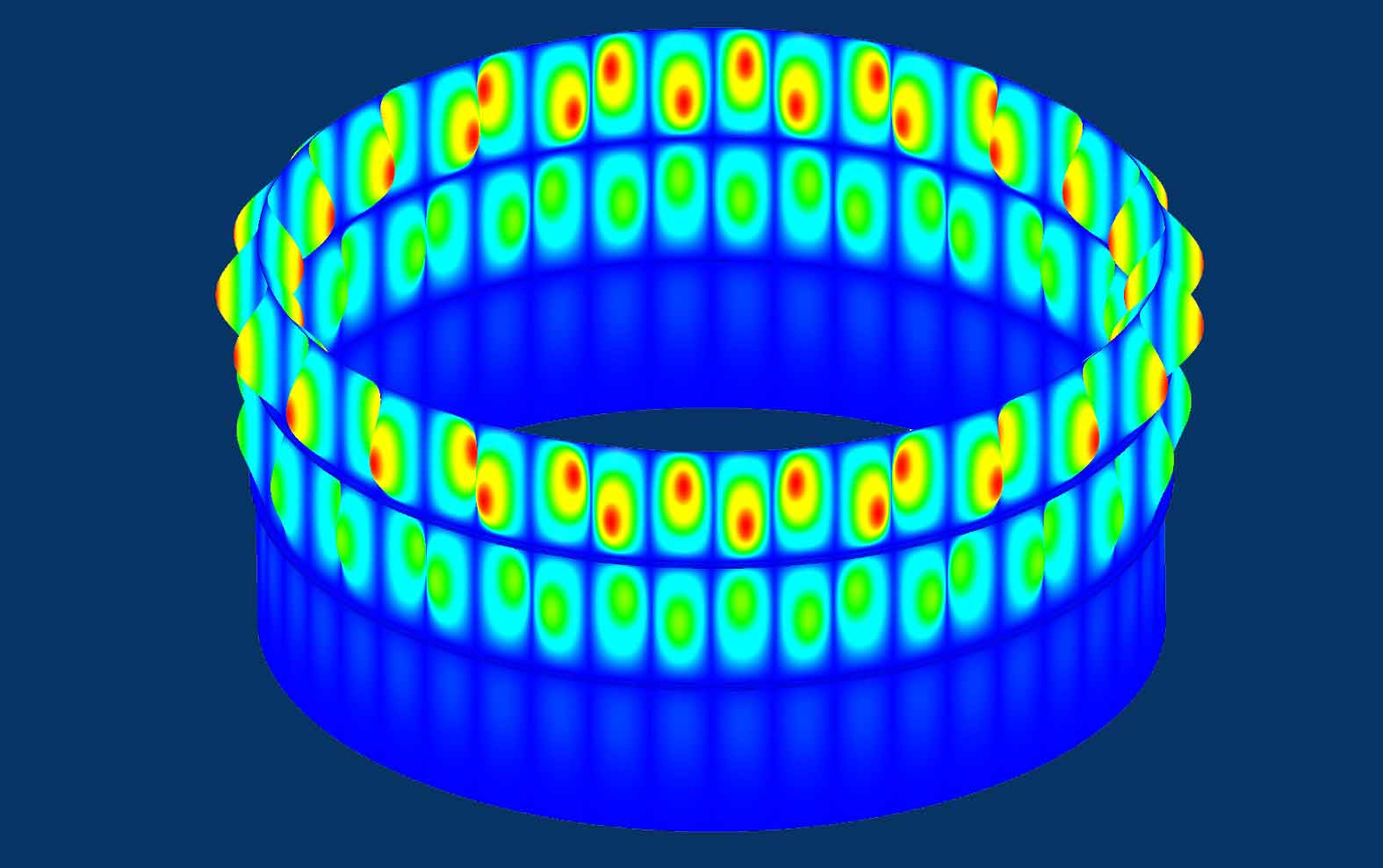

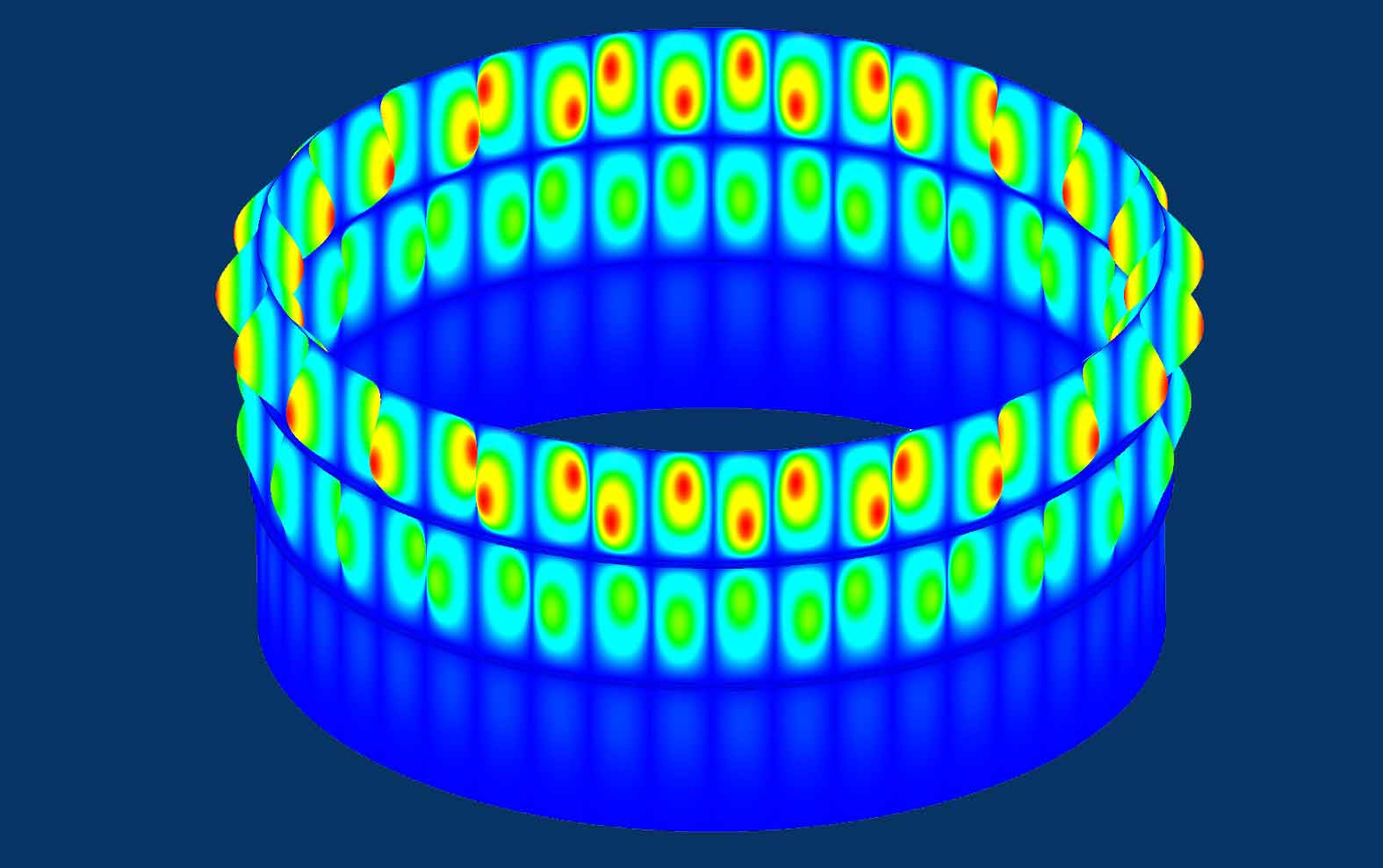

Shell buckling analysis

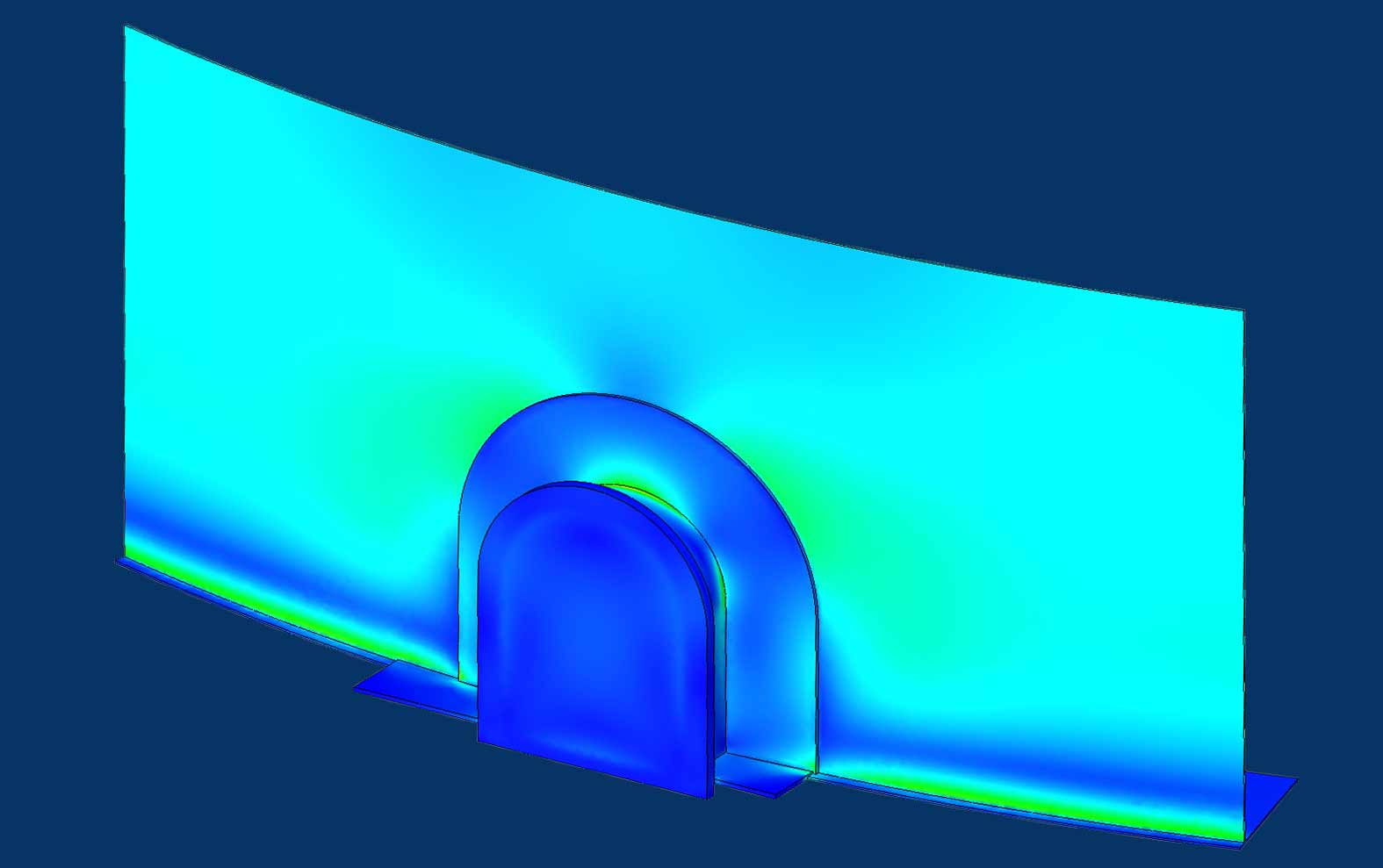

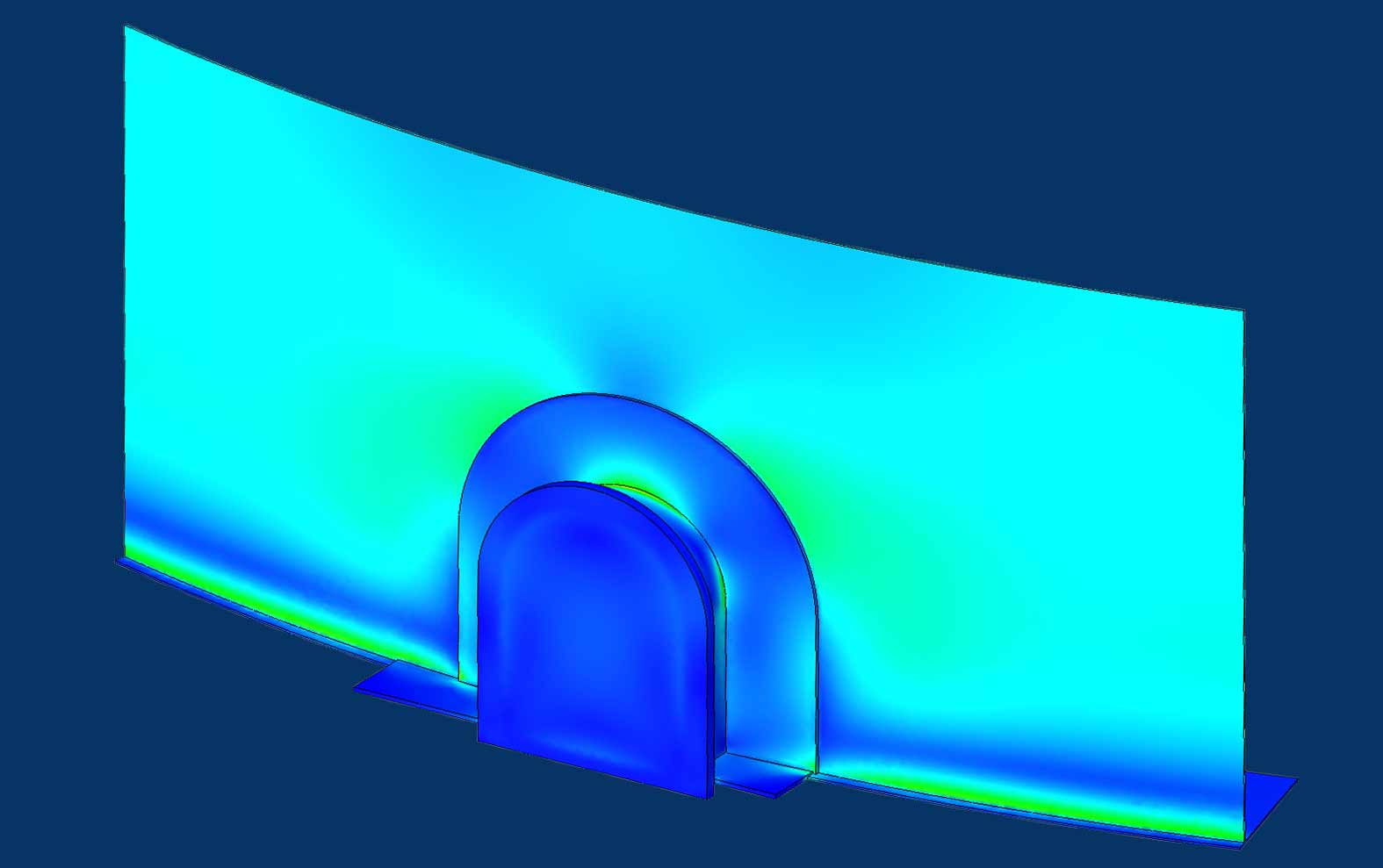

Cleaning opening strength analysis

Tank shell strength analysis

Faccin sheet metal roller

• Sheet width 3000 mm

• Sheet thickness up to 60 mm

Zinser flame cutting machine

• CNC controlled (plasma and oxyfuel)

• Firing table 3000 mm wide and

24000 mm long

• Sheet thickness up to 150 mm

Excavator bucket repair

“Everything from a single source”

Burning, rolling, drilling (mobile also on-site), welding

Faccin profile roller

• Profiles up to HEA 300

• Pipes up to 168 mm in diameter

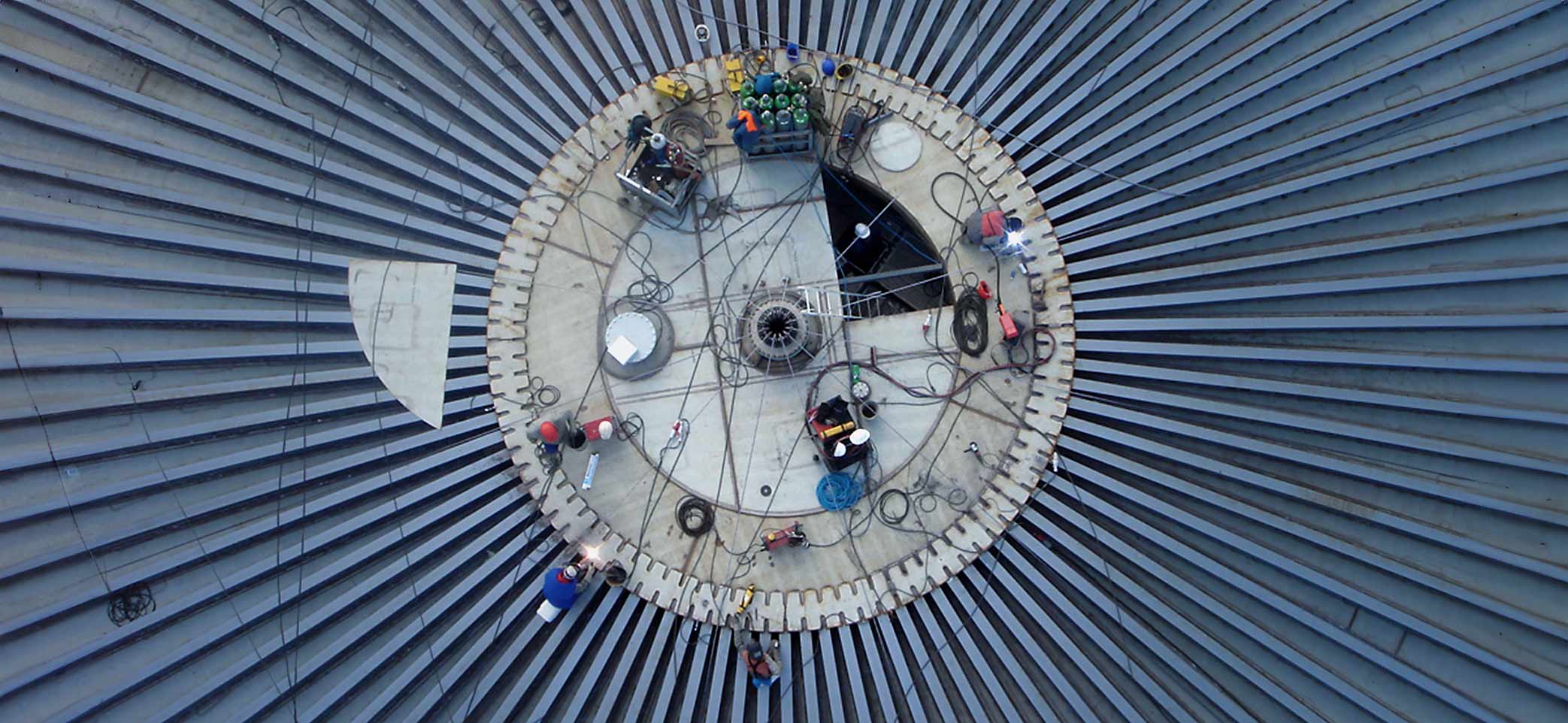

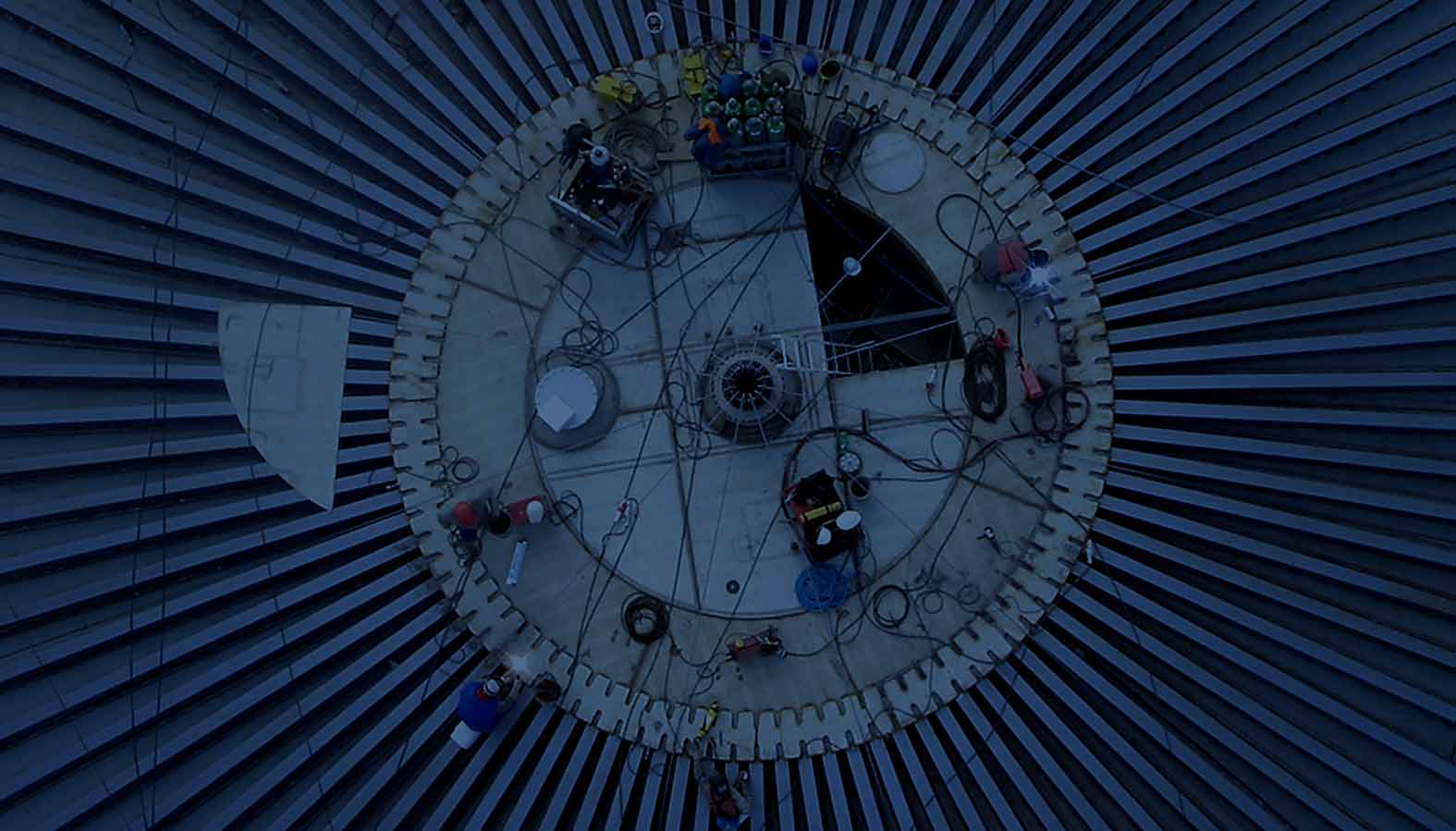

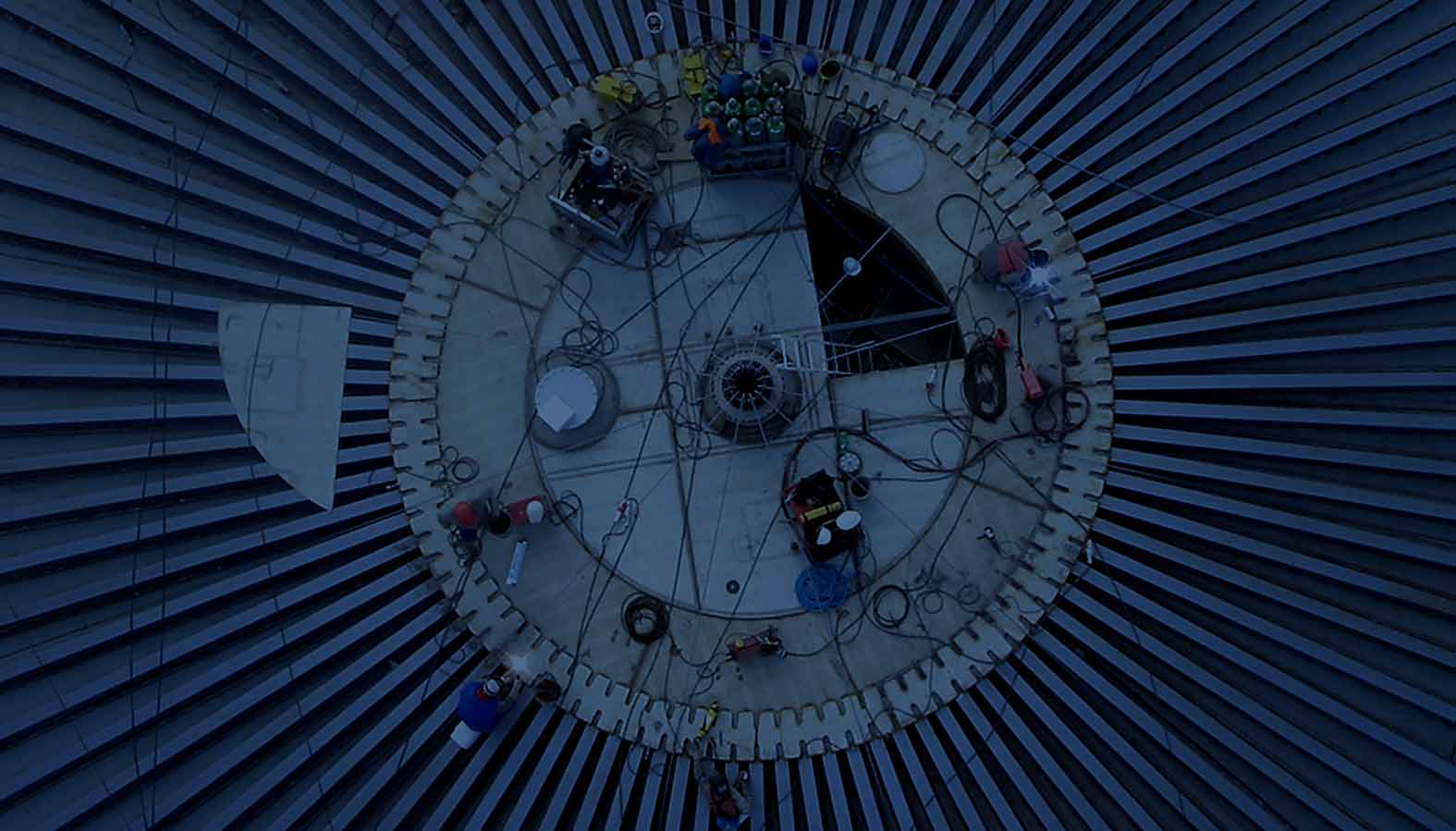

Installation of a syrup tank

Installation of a stainless steel tank with cup

Installation of a rolling ladder

Installation of the membrane

Construction

Statics

Production

Installation

In addition to focusing on the trouble-free completion of functioning tank systems, we are always looking for and developing optimised solutions. The results of this work include our own patents, such as the JPM SWING I floating roof seal, the SWING II floating roof seal and a rope guide for low-pressure gas storage tanks.

Not quite our core business, but also part of our range of services: repair of heavy equipment such as excavator buckets, push plates for bulldozers or mobile drilling on wheel loaders.

CAD overview drawing

Creation of a 3D model

Bill of material

CAD drawing creation

Fixed roof strength analysis

Shell buckling analysis

Cleaning opening strength analysis

Tank shell strength analysis

Faccin sheet metal roller

• Sheet width 3000 mm

• Sheet thickness up to 60 mm

Zinser flame cutting machine

• CNC controlled (plasma and oxyfuel)

• Firing table 3000 mm wide and

24000 mm long

• Sheet thickness up to 150 mm

Excavator bucket repair

“Everything from a single source”

Burning, rolling, drilling (mobile also on-site), welding

Faccin profile roller

• Profiles up to HEA 300

• Pipes up to 168 mm in diameter

Installation of a syrup tank

Installation of a stainless steel tank with cup

Installation of a rolling ladder

Installation of the membrane

|

|

|

|

|

| |

JPM INGENIEURTECHNIK GMBH

Heideweg 2 |24558 Henstedt-Ulzburg |

P +49 (0) 4193 / 9 05-0

|

|

| |

JPM INGENIEURTECHNIK GMBH

Heideweg 2 |