-

Design code: EN, EUROCODE, DIN, API, ASTM, ASME, BS, CODRES, etc.

Applications: Mineral oil, chemicals, foodstuffs, H2O, liquefied gases, heat storage

Material: Carbon steel, stainless steels, etc.

Temperature range: From -200°C to +300°C

Pressure design: From atmospheric pressure to approx. 500 mbar

Sizes: From approx. 1000 m3 capacity

Tank bottom: Flat bottom overlapped or butt-welded, fully supported or on support grid, with or without slope or also designed as conical bottom

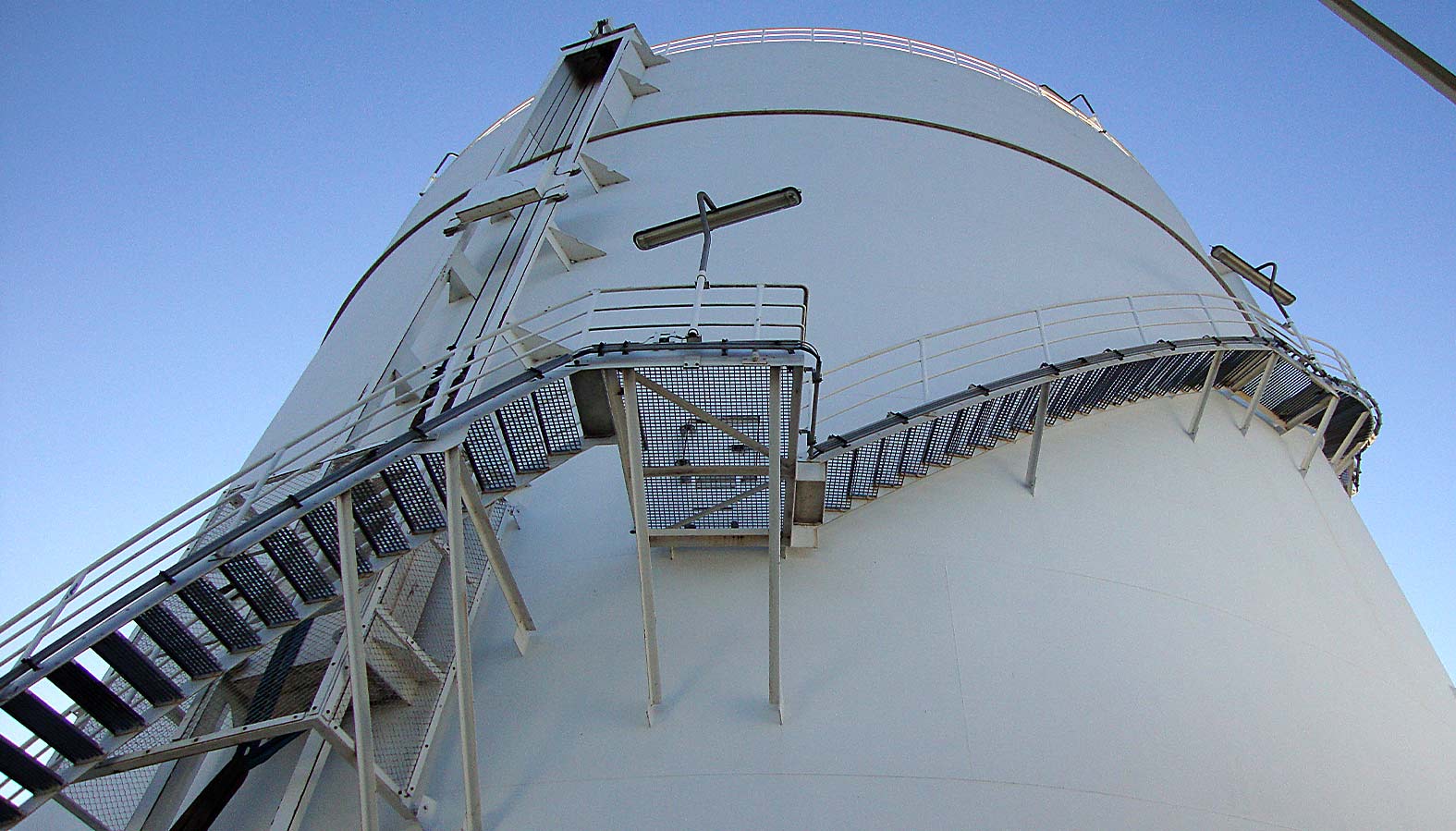

Fixed roof types: Self-supporting domed roof or self-supporting conical roof

Internal floating roofs: Full contact – pontoon type internal floating roofs equipped with the JPM SWING II floating roof seal

The operating and safety equipment required for trouble-free operation of the various applications is selected and dimensioned by our engineers in accordance with the applicable standards:

Sprinkler system as a cooling system for protection against fires in adjacent structures

Foaming system as a fire extinguishing system

Various internal and external heating systems for temperature control of stored products

Overpressure and underpressure valves

Overfill protection

External access equipment consisting of stairs, ladders and platforms

Internal access equipment such as manholes and bottom-level cleaning openings

Equipment for leakage monitoring of tank bottom and tank shell

Tank anchoring in coordination with the available foundations

We supply and install additional equipment required for safe operation, such as inlet structures, immersion pipes, floating suction systems, skimmers, diffusers, agitators, etc.

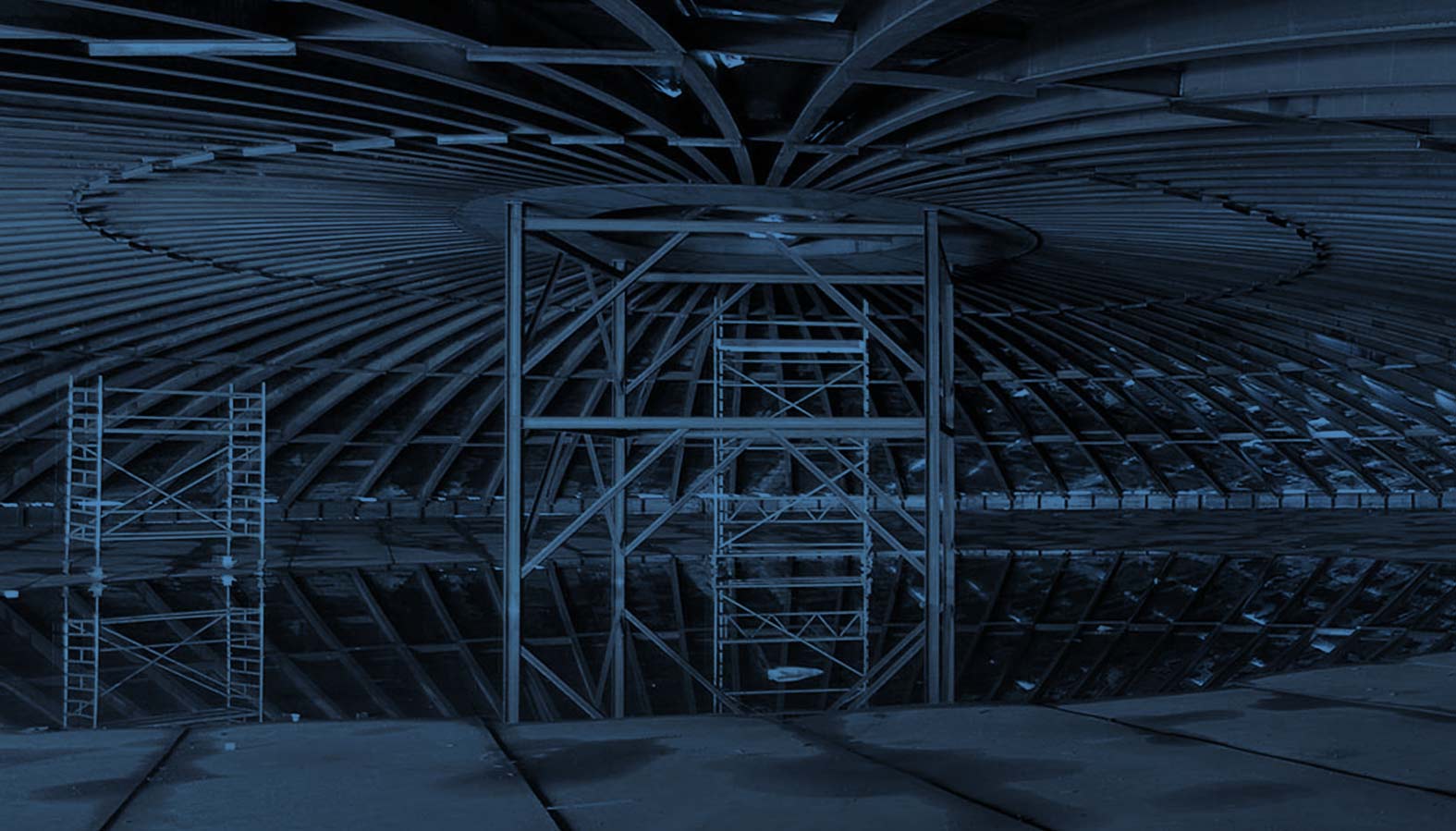

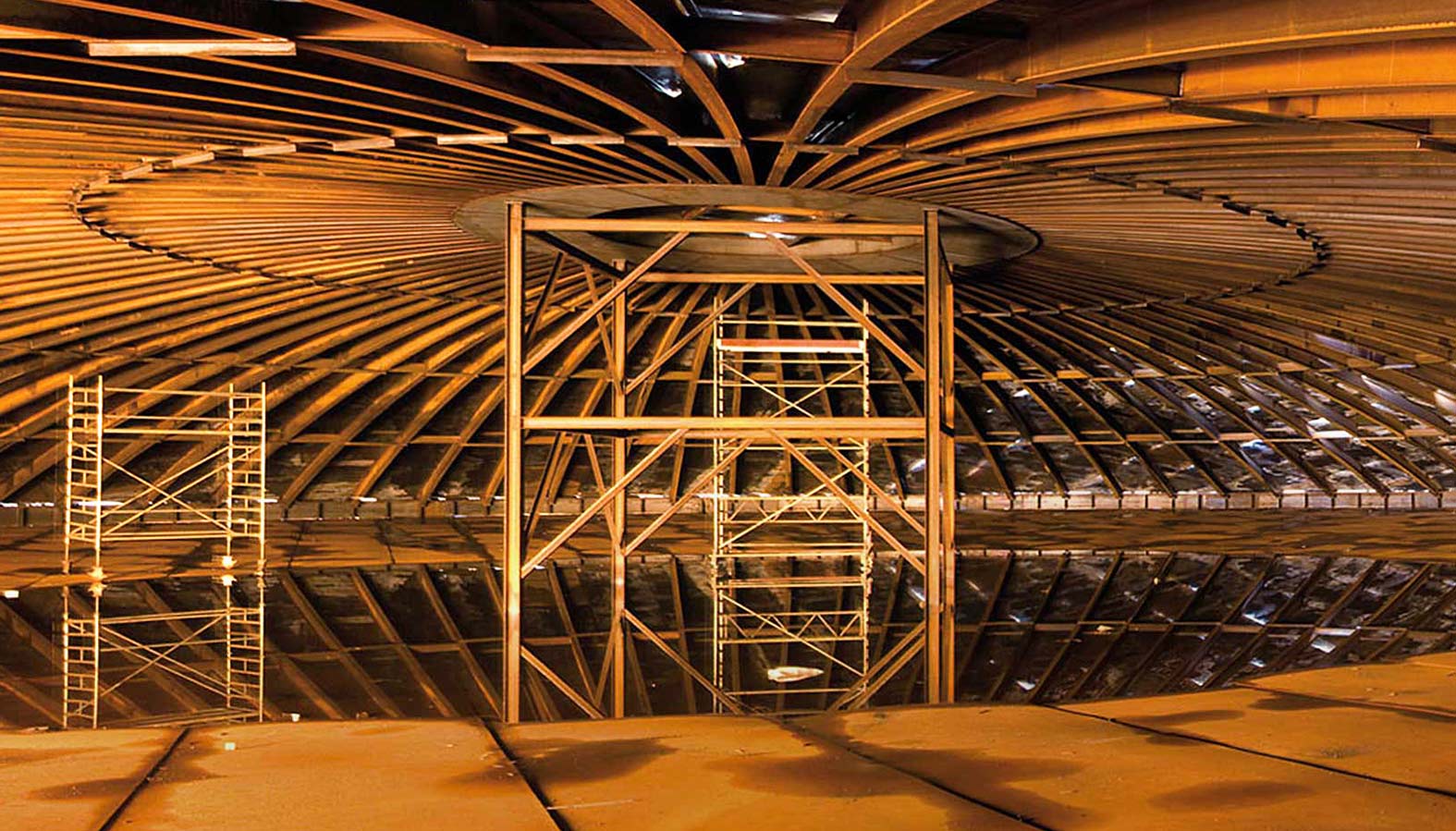

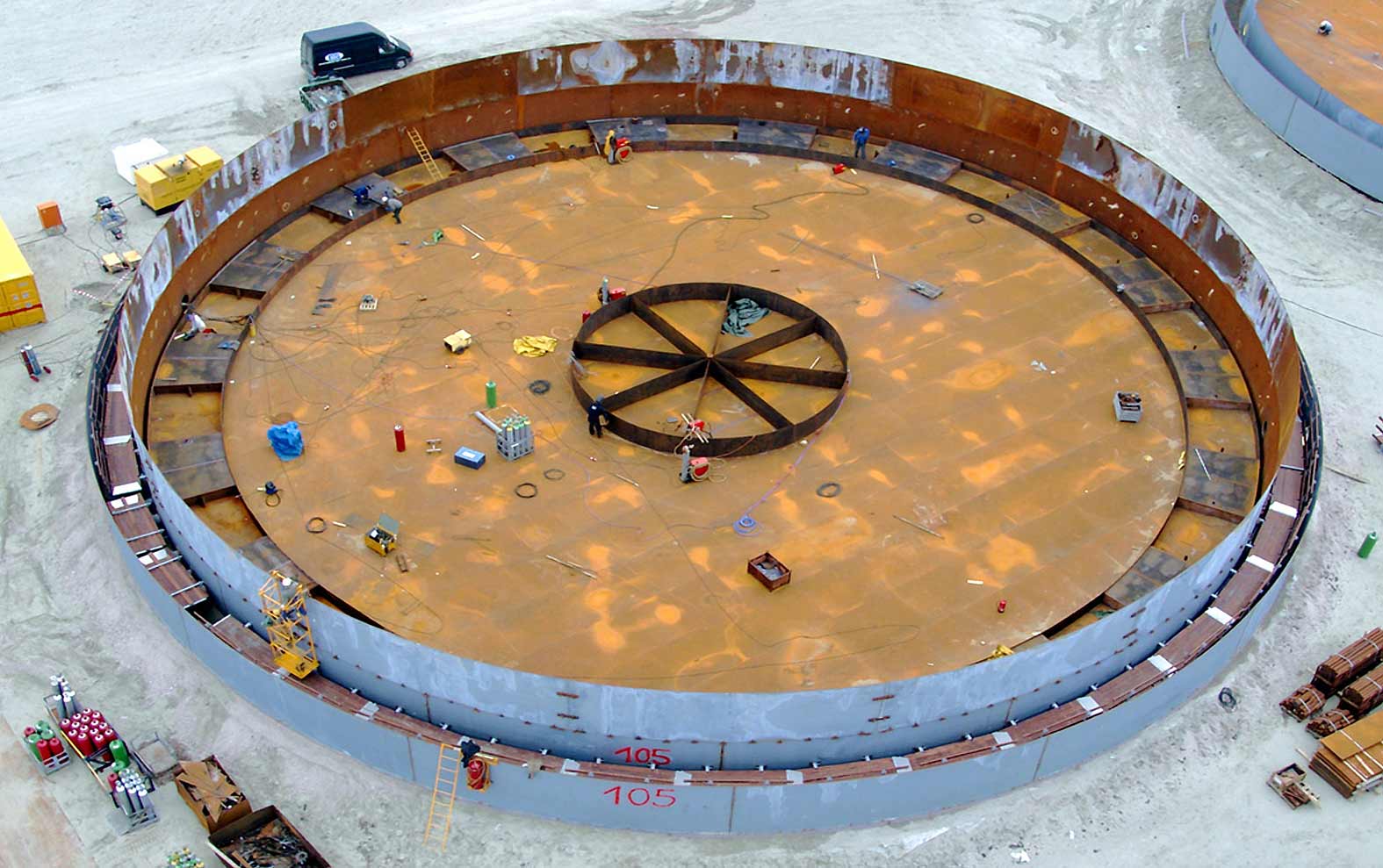

Interior view of a storage tank with a diameter of 60 m

Storage tanks made of stainless steel, various designs and sizes up to 16,000 m³, partly as special design

Construction of a 10,000 m³ fixed roof tank for 68% isotropic nitric acid made of stainless steel with a special chemical composition

Construction of a new 60,000 m³ fixed roof tank with external rafters for the storage of special products

-

Design code: EN, EUROCODE, DIN, API, ASTM, ASME, BS, CODRES, etc.

Applications: Mineral oil, chemicals

Material: Carbon steel, stainless steels, etc.

Temperature range: From -20°C to +80°C

Pressure design: Atmospheric pressure

Sizes: From approx. 5000 m3 capacity

Tank bottom: Flat bottom overlapped or butt-welded, fully supported or on support grid, with or without slope

Floating roof types: Pontoon type floating roof, also with centre pontoon and double-deck floating roof, each equipped with the JPM SWING I floating roof seal

The operating and safety equipment required for trouble-free operation of the various applications is selected and dimensioned by our engineers in accordance with the applicable standards:

Sprinkler system as a cooling system for protection against fires in adjacent structures

Foaming system as a fire extinguishing system

Various internal and external heating systems for temperature control of stored products

Overpressure and underpressure valves

Overfill protection

External access equipment consisting of stairs, ladders and platforms

Internal access equipment such as manholes and bottom-level cleaning openings

Equipment for leakage monitoring of tank bottom and tank shell

Tank anchoring in coordination with the available foundations

We can also provide additional equipment required for safe operation, such as inlet structures, immersion pipes, floating suction systems, skimmers, diffusers and agitators.

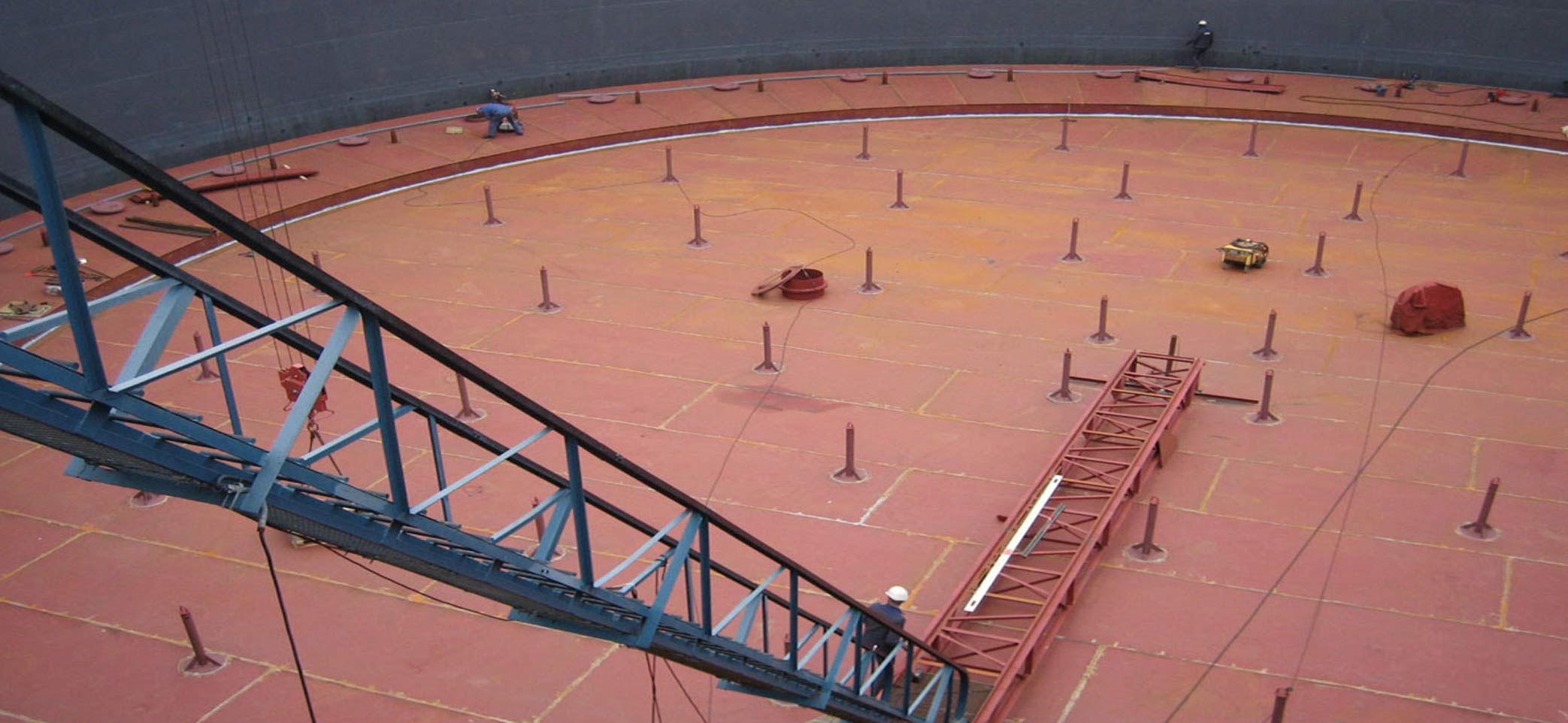

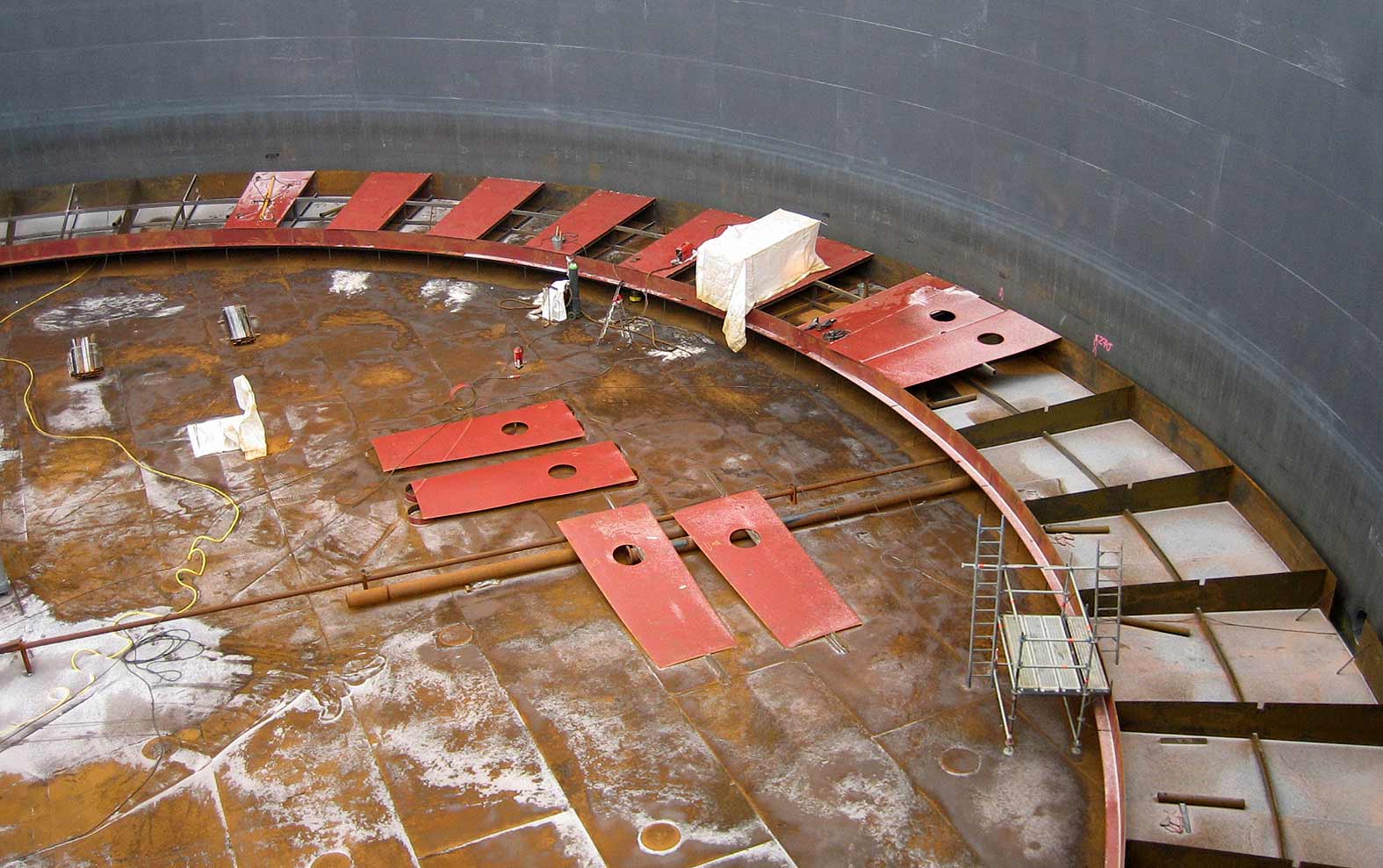

Construction of a fixed roof tank with steel collection pan and start of construction of the internal floating roof with a diameter of 42 m

Installation of the membrane

Floating roof drainage for draining rainwater from the top of the floating roof

Installation of the outer pontoon cells

-

The JPM low-pressure gas storage tank meets the requirements of TA-Luft and the VdTÜV Technical Leaflet No. 954.

The membrane, shell and rope guide are used in storage tanks in accordance with DIN 4119/ EUROCODE. Retrofitting in existing storage tanks has been successfully implemented several times.

For higher operating pressures, the membrane can be made of steel and weighted with adjustment weights, for example, made of concrete.

For special applications, such as storage of acetylene or blast furnace gas, JPM plans and builds bell type gas storage tanks.

Bell type gas tank with a capacity of 16,500 m³ for the storage of acetylene, operating pressure 60 mbar, total height 53 m

Guide roller for the bell in the dip tank

Membrane gas tank with external counterweight

Bell type gas tank with a capacity of 16,500 m³ during installation

-

1. Tank foundation

Tank lifting and renewal of the foundation under the tank

Relocation of the tank with a crane to renew the foundation

Installation of an additional concrete layer/insulation layer into the tank

2. Tank bottom

Repairs such as the replacement or doubling of bottom plates or the re-welding of weld seams Subsequent installation of tank bottom sumps or a new bottom

Subsequent installation of a vacuum-monitored double bottom system in accordance with DIBT approval Replacement of bottom edge plates and plates of the lower first shell section

3. Tank shell

Replacement of corroded shell plates

Raising of the tank shell to increase volume

Installation of additional stiffening rings on the tank shell

4. Fixed roof

Repair or replacement of the sheet metal skin

Repair or replacement of the roof rafters

Additional stiffening of the existing fixed roof

Replacement of the entire fixed roof

5. Floating roof and internal floating roof

Repair or replacement of the membrane or pontoon

Leak test of the pontoon

Conversion of pontoon floating roof into double-deck floating roof

Repair or replacement of existing floating roof seals

Delivery and installation of new JPM SWING floating roof seal

Retrofitting of JPM DOUBLE SWING secondary seal

Retrofitting of JPM TERTIARY SWING tertiary seal

6. Equipment

Nozzles and manholes

Access systems

Floating suction, skimmers

Tank heaters

Safety fittings

Fire extinguishing equipment

Floating roof drainage systems

7. Upgrading of existing tanks

Conversion of floating roof tanks into fixed roof tanks

Retrofitting to internal floating roofs

Retrofitting of approved vacuum-monitored double bottom systems in accordance with DIBT approval

Retrofitting of vacuum-monitored double shell systems

Volume increase

Change in design parameters

Adaptation to new storage products

Adaptation to applicable standards

Static recalculation of tanks for new operating parameters or taking corrosion erosion into account

Lifting of 2 newly manufactured stainless steel drainage bins, each weighing approx. 160 tonnes

Increasing the volume of a tank by installing 6 new lower shots

Renewal of a tank roof on a 24 m diameter bitumen tank

Replacement of a cone bottom with nozzles

|

| |

JPM INGENIEURTECHNIK GMBH

Heideweg 2 |