Gas storage

![]() is designing and building gas storage for different needs and in different designs.

is designing and building gas storage for different needs and in different designs.

The JPM low pressure gas holder is for example often used for the temporary storage of waste gases from a tank farm in front of a vapour recovery unit or in front of a flare. The working pressure of low pressure gas holder is about 1 to 5 mbar.

![]() has developed and patented a gas holder membrane guidance according to the stunt kite principle for low pressure gas holder, which ensures a safe operation of the gas reservoir. The membrane and the reverse-drawing tank shell are made of highly tear resistant material and is resistant against hydrocarbon compounds. The ropes, pulleys and bearings of the membrane guidance is located below the membrane so that an optimal guidance is ensured.

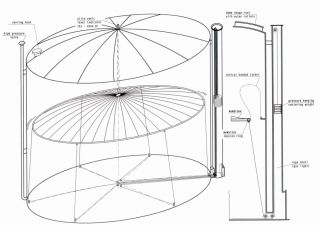

has developed and patented a gas holder membrane guidance according to the stunt kite principle for low pressure gas holder, which ensures a safe operation of the gas reservoir. The membrane and the reverse-drawing tank shell are made of highly tear resistant material and is resistant against hydrocarbon compounds. The ropes, pulleys and bearings of the membrane guidance is located below the membrane so that an optimal guidance is ensured.

The JPM low pressure gas holder meets the requirements of the Clean Air Act and the VdTÜV bulletin No. 954.

The Membrane reverse-drawing tank shell and the membrane guidance can be used in storage tanks in accordance with DIN 4119. A retrofit into existing storage tanks is possible and has already been implemented several times.

For higher operating pressures steel made membrane can be used and they can be complained with calibration weights e.g. with concrete weights.

For special applications, the JPM gas holder is equipped with an upper guide tube and a steel disc membrane.

The tank shell and the roof steel membrane resp. the steel disc is sealed with a reverse-drawing tank shell.