Floating roof seals

![]() has a specially developed highly efficient sealing system of different size for the use in storage tanks to close the annular gap between the tank shell and the floating roof outer rim.

has a specially developed highly efficient sealing system of different size for the use in storage tanks to close the annular gap between the tank shell and the floating roof outer rim.

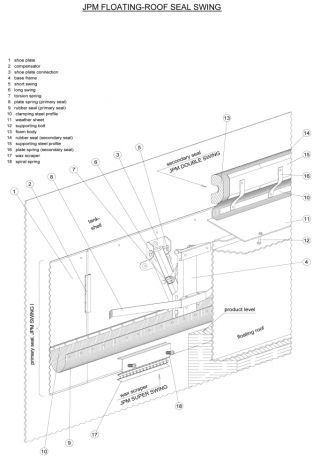

Reducing emissions through the JPM floating roof seal system SWING complies with the legal requirements. This is demonstrated by comparative emission calculations according to API code.

The JPM sealing system consists of the following components:

- Primary seal for external floating roofs (SWING I (SWI))

- Primary seal for internal floating roofs (SWING II (VT II))

- Secondary seal (DOUBLE SWING (DSW))

- Tertiary seal (TERTIARY SWING (TSW))

- Wax scratches (SUPER SWING (SSW))

Secondary seal DSW, tertiary seal TSW and wax scraper SSW can be combined with each of the primary seals SWI and SWII.

The large range of motion of the seal can compensated large annular gap width differences and also any buckling of the tank shell.

The specially designed double lip is tightening the annular gap optimally even when driving over welds.

The combination of strong springs and pantographs centres the floating roof in the tank and thus allows the operation of floating roofs without bumpers.

The materials used and the highly abrasion-resistant blanket ensures maintenance-free operation for many years. The seal is resistant against UV radiation and aromatic hydrocarbons.

The construction of the floating roof seal SWING I allows inspection of the seal during operation without direct contact with the stored medium.

Special construction on request.